After a decade of rapid growth, vehicle electrification is here to stay. To stay competitive, it is crucial for vehicle manufacturers, OEMs, and flexible startups to improve their product development processes. New electric vehicle (EV) concepts increase the need for effective durability engineering to better understand customer usage and the impacts of lightweight designs and new systems with heavy vehicle batteries. And with an innovative road load data analysis solution, development teams can speed up time-consuming tasks such as load data consolidation, data validation, accurate rainflow counting, and experimental fatigue analysis.

Watch the on-demand webinar and discover the advantages of using Siemens Simcenter solutions to:

- Generate and run processes up to 50% faster than traditional solutions

- Create damage equivalent and accelerated test profiles

- Foster team collaboration with straightforward use

Speed up time-consuming durability tasks in road load data analysis

Analyzing durability potential during road load data analysis has many time-consuming challenges. There are laborious load data comparisons needed to qualify and quantify the durability potential of vehicle loads. Engineers need to map exact customer usage into realistic and replicable targets due to the demand for realistic targets. And for fatigue life predictions, they must compare design options by estimating fatigue life from measured stress or strain. With Siemens Simcenter solutions, engineers can qualify and quantify the durability potential of vehicle loads with innovative load analysis technology. They can also take the market and customer into account by synthesizing customer-correlated durability targets and comparing design options for long-term quality by estimating fatigue life from measured stress or strain histories.

Secure high-grade consolidated and accurate road load data

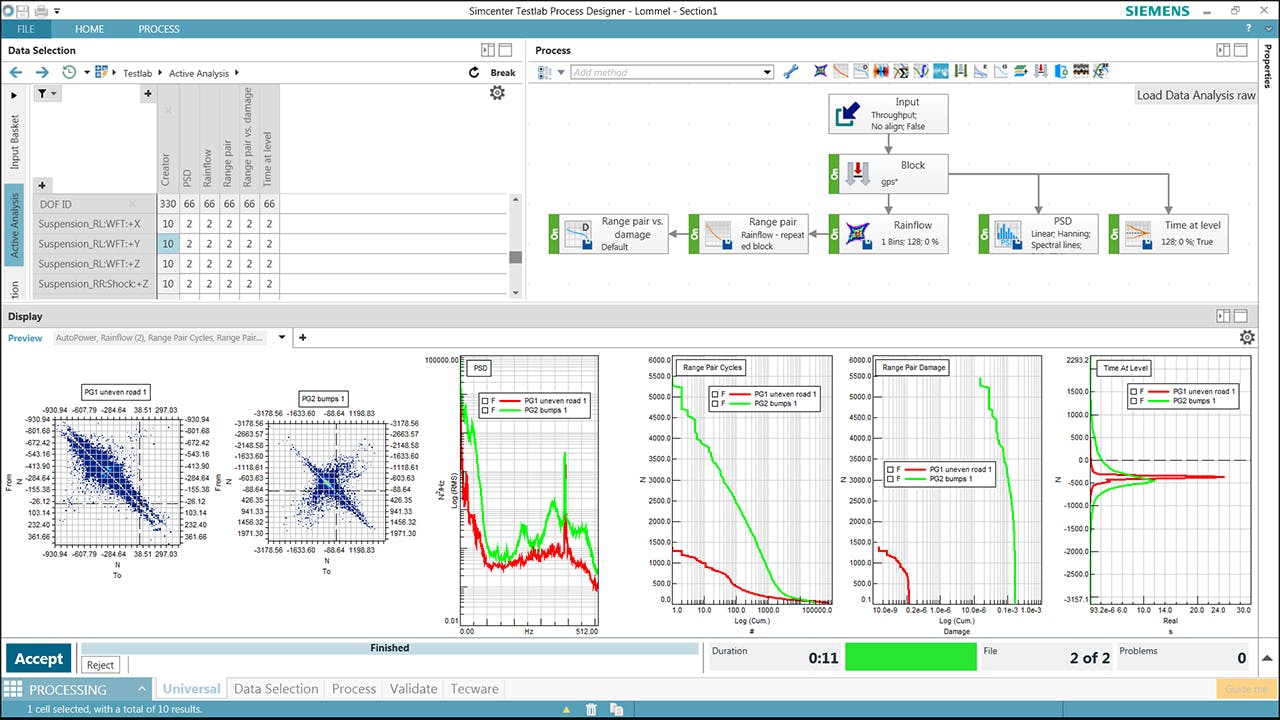

Validating acquired road load data comes with a different set of challenges. The amount of data can be cumbersome, so engineers need a quick and efficient way to compare many channels and runs. Manual data analysis is also time-consuming and sensitive to human errors. Lastly, unconsolidated data may lead to wrong stress and fatigue assessments due to anomalies in acquired data. Siemens Simcenter solutions enable fast, easy, and intuitive validation of raw time signals, including a broad set of analyses. Engineers can gain confidence in their data with automated processes securing the best, high-grade consolidated, and accurate load data to use as an input to both physical and virtual validation.

Accelerate the delivery of critical insights and create reliable simulations with road load analysis

Lack of process standardization, inefficient reporting, and time-consuming data conversions must be addressed to accelerate the delivery of critical insights and create reliable simulations. There must be actionable reporting, and process sharing across different teams before the simulation or test engineer uses road load analysis data to make accelerated test schedules for simulation, test benches, or proving ground. Siemens Simcenter solutions allow teams to build processes based on in-house procedures and share them on the company level or with suppliers. This enables better collaboration by making reporting accessible with single-click interactive reporting, accelerating decision-making during team meetings.

In this on-demand webinar, learn how to perform and speed up road load data analysis, set accurate durability targets, get more valuable insights from load measurements, and optimize the durability engineering process. Register to watch now!