Over the past decade, simulation in the heavy equipment industry has exploded to explore new designs while reducing costly prototyping phases. Simulation is used in various engineering domains such as thermal, structural integrity, hydraulics, NVH and more. Consequently, the number of models, analyses, and data has increased considerably.

Watch this on-demand webinar to learn more about how simulation process and data management (SPDM) software aids engineers in predicting product performance while also improving collaboration and efficiency between engineering departments.

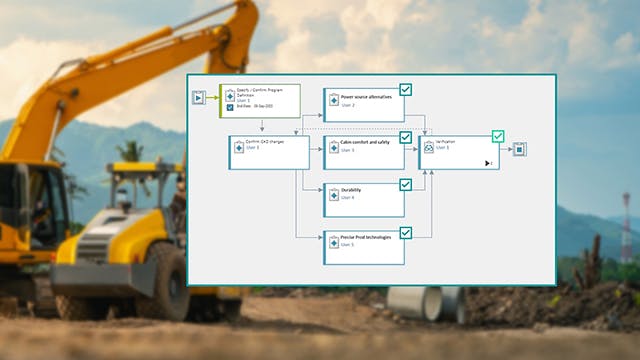

MBSE integrated with PLM

By integrating MBSE with PLM you can define what will be built, instruct people how to do it and orchestrate the downstream development process. This creates the critical glue that holds the entire cross-product lifecycle together.

Transparent access to all engineering analyses, using the latest in data models, and smooth interactions and traceably among all engineering departments remains crucial when it comes to the simulation process. Design decision-making must be streamlined to ensure engineering departments save time and money.

Verification management framework

Heavy equipment manufacturers are under increased pressure to develop more complex, integrated machines with compressed delivery times with the expectation of high initial product quality and production rate product costs. You can achieve both of these objectives with our verification management solution for the heavy equipment industry. This framework enables manufacturers to combine unique capabilities for integrated simulation and test management with plant simulation for manufacturing planning and execution, all while ensuring complete closed-loop requirements traceability.

Teamcenter simulation

Discover how Simcenter solutions can be used in an end-to-end process with a new requirement request for design changes. This is possible through Teamcenter for Simulation (TCSim) which allows a smooth workflow along the program definition.

Learn more about the components of a successful model-based system engineering deployment by registering for this on-demand webinar.

Meet the speakers

Gaétan Bouzard

Simcenter Heavy Equipment Industry Lead

Vijay Singh

MBSE Solution Consultant

Singh is an MBSE expert consultant in the industry strategy team of the simulation and test solutions segment. In this role, he is responsible for enabling industry-leading customers to successfully integrate their simulation and test workflows as part of their enterprise MBSE solution.