Detecting defective and counterfeit components is a massive problem in today's market. Significant shortages in the component supply chain force manufacturers to work outside their trusted supplier network and expose them to substantial risk. Existing traceability solutions don't provide sufficient component-level protection since they only test small samples.

Watch this on-demand Siemens webinar with Cybord to learn about new ways to secure the electronic component supply, mitigate risk and ensure traceability.

Secure electronic component supplies, mitigate risk, and secure manufacturing traceability with visual data and AI

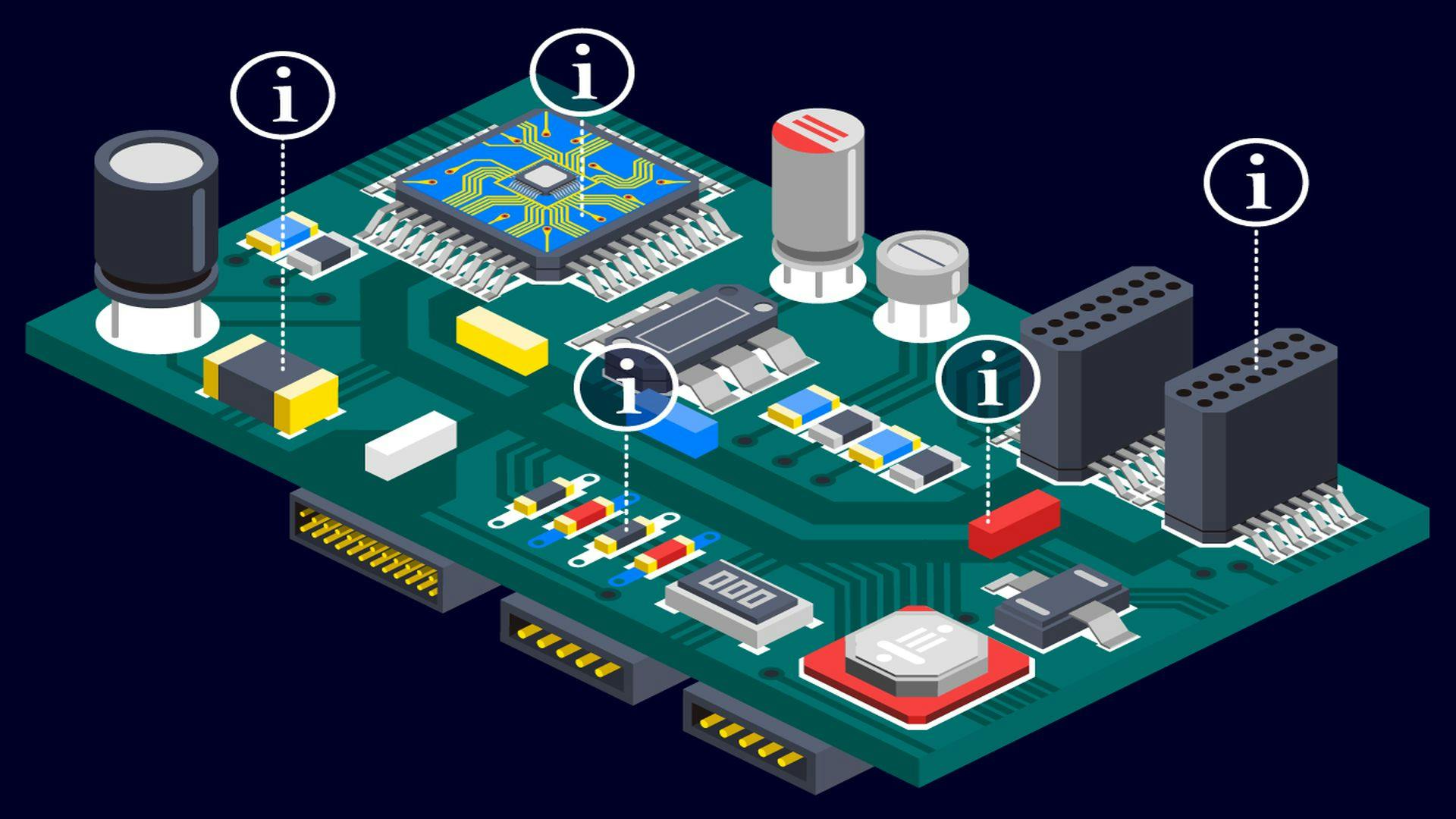

Electronics manufacturers can improve product reliability and secure effective material sourcing with traceability using visual inspection of 100% of the components on a PCB. Artificial Intelligence (AI) can determine component authenticity and condition in real-time, verifying the material sourcing fit.

- Utilize images from SMT assembly machines to verify components

- Learn how to provide 100% traceability to your customers

- Discover how to minimize costly recalls

Visually inspect 100% of the components on a PCB with visual data and AI quality control to detect defective parts

Using visual data and AI quality control, manufacturers can detect defective parts quickly and before distribution. Cybord's software-as-a-service (SaaS) solution utilizes images taken by surface mount (SMT) assembly machines. It pairs them with proprietary artificial intelligence (AI) to determine whether every component is authentic and in good condition in real-time. It enables surgical traceability of defective parts and counterfeit components, allowing manufacturers to minimize costly recalls.

Enable manufacturing traceability of defective parts and counterfeit components

Component faults cause 8 out of 10 product failures, raising the risk of recalls. Imagine having a complete record of manufactured components, discovering an issue with quality and identifying who was sent items from that lot with those damaged or defective parts. Counterfeit components are no longer an issue as AI quickly identifies and flags these components.