Turbomachinery CFD simulation software for designers demystifies engineering complexity, reduces product development time, and provides performance insight from an early stage.

To be competitive in the turbomachinery industry, companies rely on innovative technologies to provide high-performing machines with minimum failure or maintenance. The turbomachinery CFD simulation software from Siemens makes it possible to analyze machine performance during its entire development stages. From an early concept stage, and allows for on-time design improvements.

In this webinar, you will learn to:

- Predict the performance of rotating machines in a designer centric turbomachinery CFD simulation software

- Develop reliable designs that withstand the thermal and mechanical operating loads

- Identify key parameters

Turbomachinery engineering

Turbomachinery Engineering provides efficient methodologies to handle complex product engineering challenges.

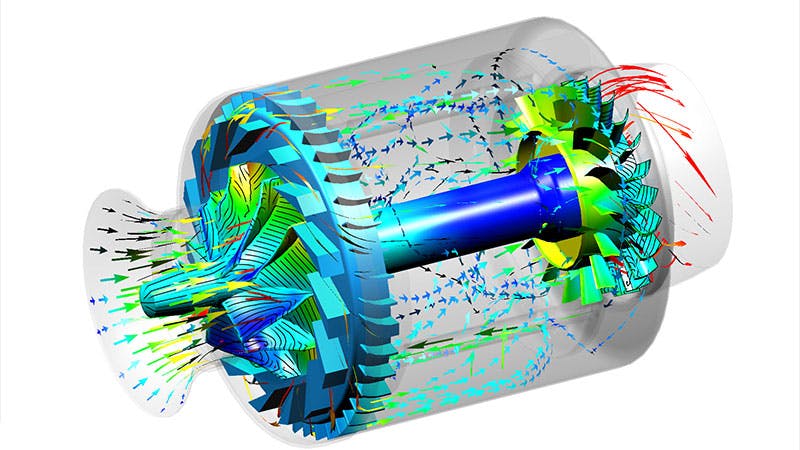

The complex geometry of turbomachines and miniature components restrict the experimental measurement of flow parameters. Thus, challenging engineers to have a better understanding of the complex flow structure. Choosing optimal single parts design using physical tests is an expensive procedure. The CFD simulation software overcomes the above limitation and provides valuable design insights for turbomachinery engineers.

Fluid dynamics solution for turbomachinery problems

Fluid dynamics solution for turbomachinery problems provides a deep understanding of the complex physical phenomena that influence performance and reliability under real operating conditions.

Using a design-centric CFD simulation software, engineers can analyze and evaluate the turbomachines as a whole unit in their preferred CAD platform. The multiCAD embedded CFD tool enables designers to visualize the simulation results on their native model.

The combination of being fully embedded into CAD systems, smart cell technology and usability allows users to focus on the turbomachinery design challenges rather than learning a new software.