Today, companies face challenges like frequently changing customer demands, shorter product lifecycles, and reduced product launch times. New technologies are crucial in realizing the flexible production systems fit to handle these challenges. With the digital twin, integration of these new manufacturing technologies is achievable in a virtual production environment using a process known as virtual commissioning. In this on-demand webinar, discover the benefits of virtual commissioning using Siemens’ software to validate a machine or system and its behavior as driven by controls to identify and resolve errors and optimize programs well before a product launch— Register to watch now!

Provide realistic validation in manufacturing with virtual commissioning

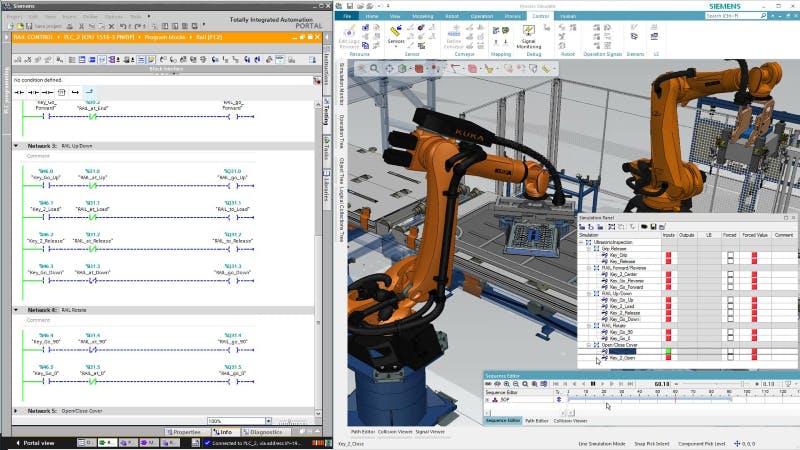

Virtual commissioning is designing and testing a virtual model of a production facility or machine. It uses 3D simulation to create a digital copy of the facility typically connected to the automation system to virtually test every aspect of production before it starts or before making changes. For example, robots can be put into virtual operation, tested, and optimized before transferring the programs to the existing facility, and new technologies can be integrated and validated.

Utilize a comprehensive digital twin to progress in digitalization

A particularly critical and sensitive phase must always occur before starting production— When mechanical, electrical, and controls engineering deliveries come together for the first time to form the production environment. Through digitalization and utilization of the digital twin, such integration is also achievable in a virtual environment. This common virtual space enables engineers to collaborate and develop simultaneously, rather than serially, at an early stage of the production system lifecycle.

Use Siemens Process Simulate VC Lite to orchestrate engineering, validation, and commissioning

With Process Simulate VC Lite, Siemens brings virtual commissioning and robotics to automotive manufacturers and suppliers. It provides users with full functionality for the development of a digital twin for use in virtual commissioning to:

- Reduced time to production startup

- Lower commissioning, debugging, and rework costs

- Less production downtime

- Opportunity to train operators virtually

Watch the on-demand webinar to learn more or start your 30-day trial today!

認識講者

Gal Snir

Product Owner

Gal Snir is a Product Owner at Siemens Digital Industries Software. He directs software development for virtual commissioning within the 3D simulation product group.

Gal joined Siemens in 2013 and worked in the engineering team before joining the product management team.

He received his B. Sc degree in Mechanical Engineering from Tel Aviv University, with a special focus on Automation and Control.