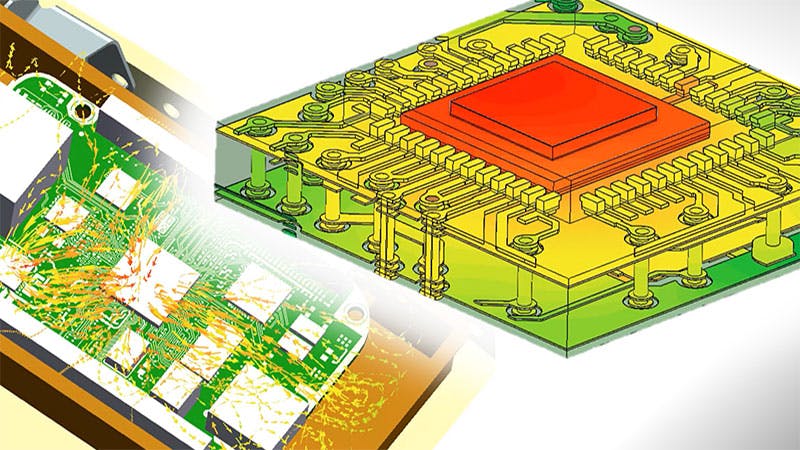

Reliable electronics require careful thermal management during design to ensure thermally induced stresses do not cause failures and to avoid throttling control performance impacts. Predicting component junction temperatures, temperature gradients and temperature cycles in operation is typically performed with electronics cooling CFD tools, to model heat transfer and fluid flow. To evaluate thermo-mechanical stress fully requires robust FEA thermo-mechanical analysis which relies on accurate 3D temperature data for thermal loads.

Learn about streamlining the use of CFD and FEA analysis for thermal and thermo-mechanical stress analysis. This presentation focuses on the workflow to generate accurate transient 3D temperature field data in CFD software and seamlessly mapping that to an FEA mesh for thermo-mechanical stress simulation.

Thermal analysis and thermo-mechanical simulation of electronics with CFD and FEA

How can you realize electronics thermo-mechanical analysis workflow efficiency? Accounting for diverse engineering teams with varied engineering skill demographics and different CAE tool usage.

Two example workflows are explored in this presentation: A fully CAD-embedded CFD and FEA analysis illustrated in Siemens NX and a workflow starting with electronics cooling specific CFD tool thermal analysis tool through to exporting 3D transient temperature results for FEA analysis into a multi-physics modeling software. Several CAE engineering user perspectives considered:

- Thermal analysts working in electronics cooling CFD environment e.g using Simcenter Flotherm XT

- Mechanical engineers and designers performing CFD in CAD e.g using Siemens NX and Simcenter FLOEFD, fully CAD-embedded CFD

- Engineers performing FEA analysis for thermal, structural, vibration, and thermo-mechanical analysis e.g using Simcenter 3D multi-physics simulation software.

Topics include electronics cooling to thermo-mechanical stress analysis

- Creating a detailed electronic cooling CFD model using MCAD and ECAD data

- Generating a 3D, CAD-based, detailed package thermal model quickly

- Incorporating ECAD data for a multilayer PCB and component mount consideration

- Evaluating component junction temperatures and PCB trace temperatures + understanding airflow

- Exporting 3D transient temperature field results from CFD and mapping to an FEA mesh easily

- Performing thermo-mechanical stress analysis of solder joints and identifying areas of design improvement

- Assessing transient temperature, stress, and strain results