Maximizing throughput and capacity—these are always amongst the goals of chemical reactor design & analysis engineers, to minimize total operational cost. Multiphysics 3-D Computational Fluid Dynamics (CFD) simulations can improve the reactor design and optimize operations by modeling all relevant phenomena, including fluid flow in complex geometries, heat transfer, hydrodynamic agitation, fluid-structure interaction (FSI), and more.

In this webinar, Nicolas Perret (Senior CFD Modeling Engineer at Solvay) will present the process by which Solvay was able to leverage the flexibility, customizability and robustness of Simcenter STAR-CCM+ to improve the thermal performance of a chemical reactor while simultaneously addressing mechanical design constraints, resulting in improvements to overall throughput & capacity.

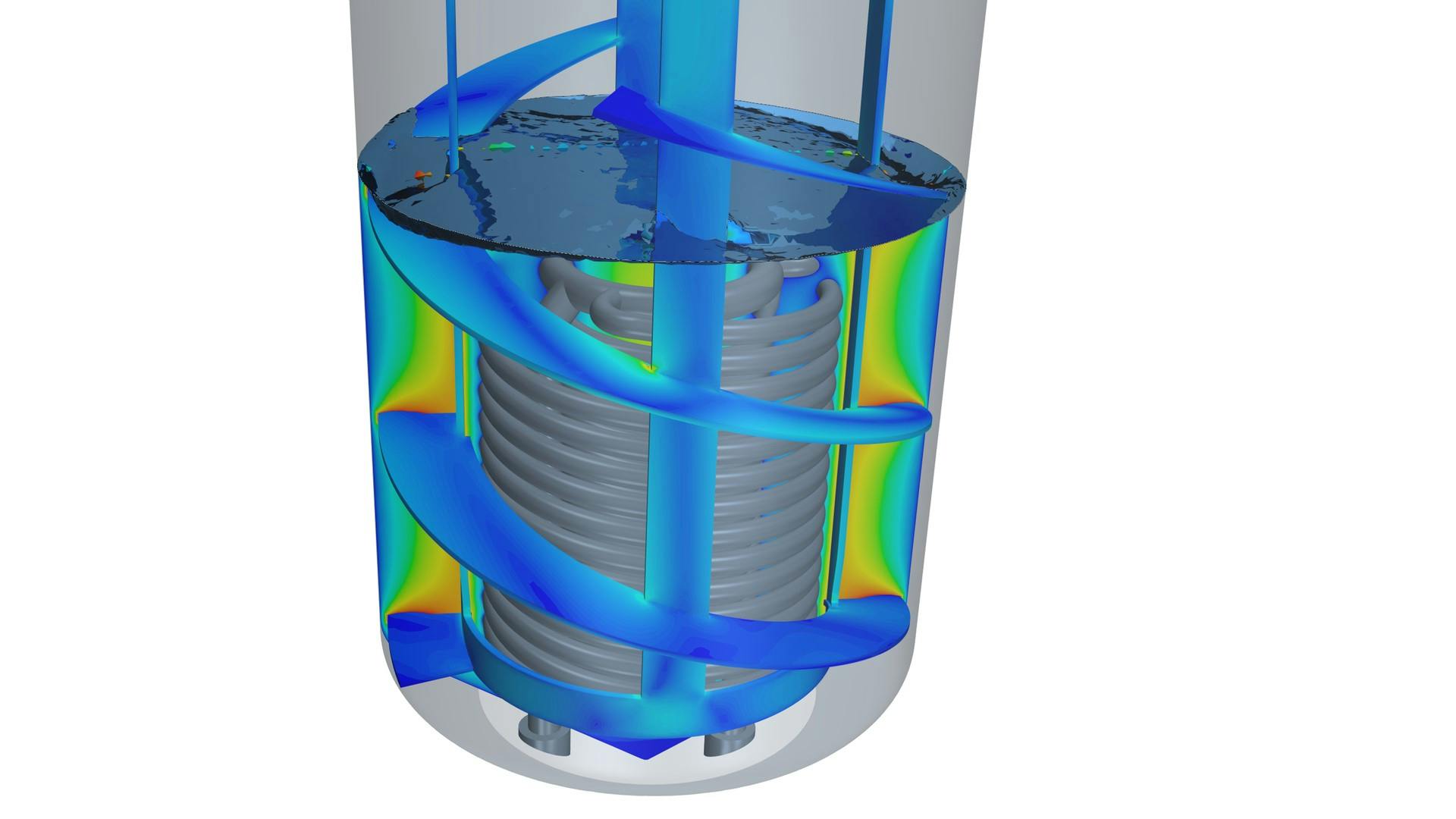

Simulations performed with a calibrated in-house 2-phase condensation model enabled the evaluation of the performance of condensing thermal fluid heating coils. These simulations provided the insight that guided the redesign of heating coil systems with improved thermal performance, leading to a significant decrease in batch duration.

In addition, the coupling of hydrodynamic prediction and mechanical resistance calculations (via FSI) enabled the Solvay engineers to validate the increased reactor capacity.

The webinar will also provide an overview of the key requirements of reactor modeling and the capabilities in Simcenter STAR-CCM+ that address them.