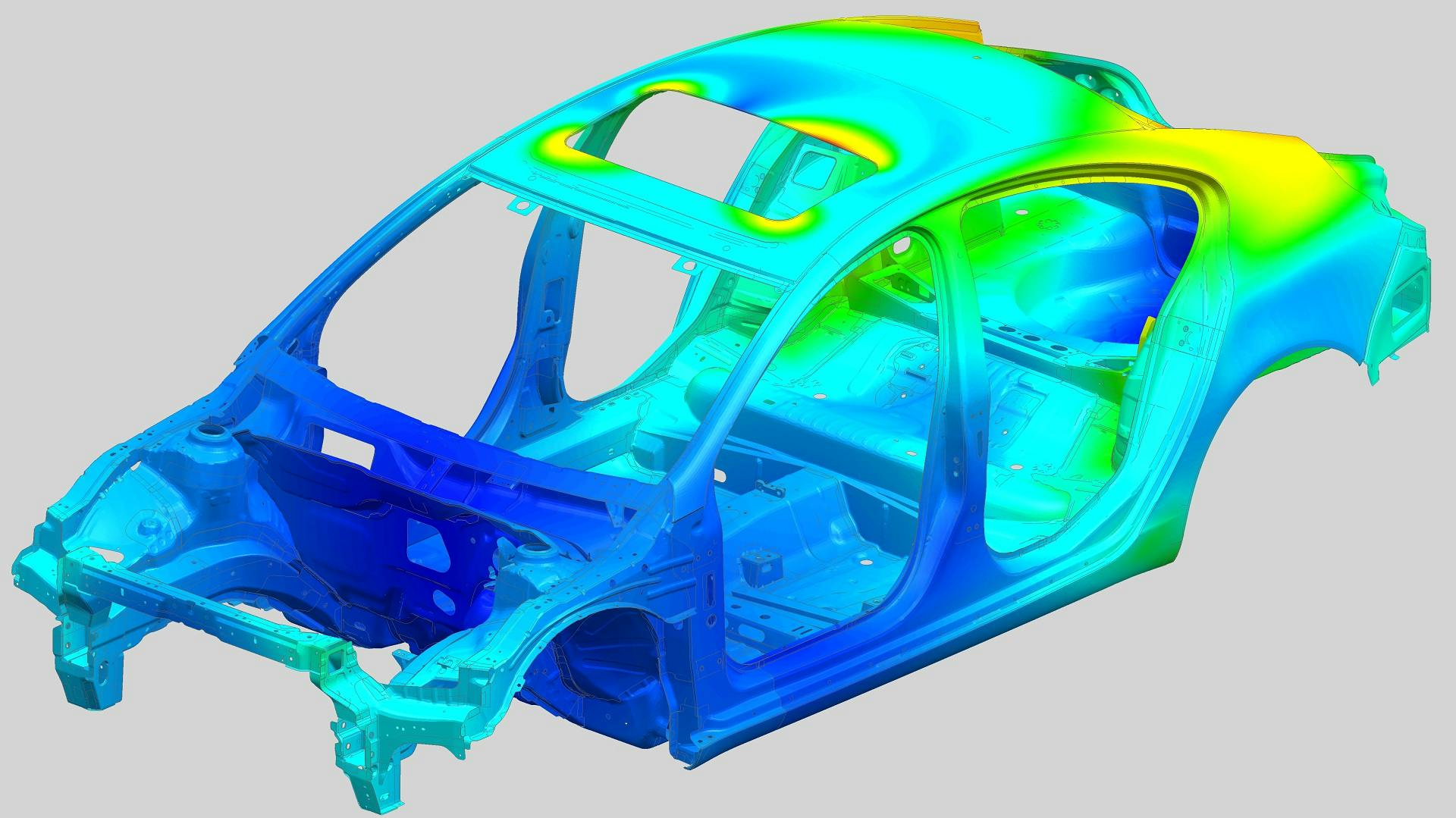

CAE engineering teams design for reduced weight of chassis, body and full vehicle, while improving and balancing the vehicle’s strength and durability performance.

But today’s 3D simulation process is too time-consuming. The transition from CAD to CAE is typically done manual, and therefore error-prone. On top of the inefficiency, it is very complex. For example, 250 CAD components of a body-in-white will eventually result in more than 1000 CAE FEM models, as multiple meshes for each component are generated for different analyses. The structural analysis process is equally laborious. There is always a compromise to be made between solver speed and accuracy, requiring different experts for linear vs non-linear, static vs dynamic, kinematic, etc. No wonder a recent study says:

“30% of analysts’ time was spent seeking or providing information. A further 32% was spent in discussions or meetings.” Rolls-Royce

With the Simcenter 3D CAE solutions, you don’t need to make compromises. Its single integrated platform for CAD and CAE, data management and optimization, offers a fast 3D simulation process and a premier FEA solver for computational performance, accuracy, reliability and scalability.

Learn how to:

- Prepare your model from CAD to CAE in 1 integrated platform

- Run structural analysis to virtually investigate product performance under all possible operating conditions

- Deal with large assemblies, such as a body-in-white or full vehicle models

- Apply integrated topology optimization and advanced materials such as composites help to develop lighter, yet stronger components

Speaker Details

認識講者

Benoit Magneville

Product Manager for Simcenter Electrification