In this webinar, you will find out how a comprehensive digital twin helps urban air mobility (UAM) manufacturers and suppliers shape urban air mobility of the future and guarantee connectivity in our cities, aiming at solutions that are inherently sustainable, affordable and safe.

Digitalization of aircraft design and certification

Advanced air mobility concepts, driven by proven electrical propulsion systems, can create a brand-new market and even disrupt the lower end of commercial helicopter portfolios.

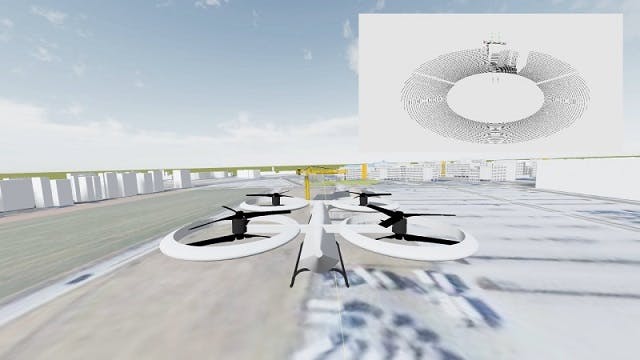

To make these products and business models a reality, companies need a deep digitalization of the development process. The digital twin allows you to “fly the aircraft before building it.” However, the UAM needs to become a reality at a certain point, and the program will “fight for its life” to obtain certification. Product design and engineering, model-based systems engineering and verification management digital threads are essential to success.

Develop urban air mobility from concept to reality

Secure UAM program execution excellence using digital twins and digital threads. Learn how to:

- Optimize the electromechanical, electromagnetic and thermal behavior to achieve the required power-to-weight ratio

- Implement a scalable modeling approach, from component level to integrated aircraft and from low- to high-fidelity representations

- Adopt a digital twin approach to de-risk the development of these novel architectures – from early concept, tradeoff studies and detailed design to verification and certification

- Manage all digital models in support of agile product development

Rolls-Royce: Pioneering electrical propulsion units for (hybrid) electric aircraft

Using Siemens digital twin technology, Rolls-Royce developed an electric motor in 9 months and 19 days, from scratch to the first test run of the prototype on the test bench. They created a digital twin of the individual components and the corresponding integrated propulsion system to optimize and verify the operations before the first eVTOL flight.

Learn from Rolls-Royce how to:

- Bring a disruptive technology, such as a UAM propulsion systems, to the market in a short time

- Fly the electric motor before building it by running multi-disciplinary analyses in one design environment

- Set up a unique toolchain for requirements engineering, configuration and quality management, as well as mechanical design, thermal management, electromagnetics and structural performance, virtual iron bird and environmental testing

Hear from urban air mobility engineering experts

Gabriele Teofili, Head of Urban Air Mobility Business Area, Rolls-Royce

Damir Filipovic, Senior Avionics Engineer, Rolls-Royce

Stephan Westphal, Quality Management, Rolls-Royce

Gunar Reinicke, EPU Lead Engineer, Rolls-Royce

Thierry Olbrechts, Director of Simcenter Aerospace Industries Solutions, Siemens Digital Industries Software