持续改进质量和减少生命周期早期故障是半导体制造商及其客户的关键目标。前几大敏感的应用包括车辆电气化、服务器、军事和国防以及消费品。

过去,半导体企业会通过电气测试或地理空间技术对减少生命周期早期故障的工作进行大力部署,旨在杜绝或测试潜在故障。老化和预测性测试技术(如零件平均测试)由来已久。此外,还有其他地理空间方法(如视觉缺陷筛选和产量聚类算法检测异常模式)也用于预测生命周期早期故障。

热测试在半导体设计中的重要性

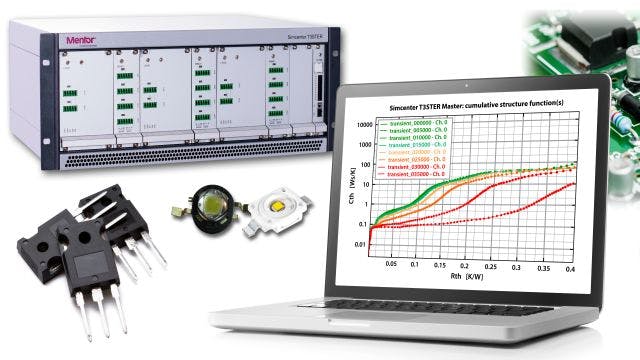

如今,零缺陷和更高可持续性已成为大势所趋,因此,企业必须减少制造错误和可变性。在线热阻测量为半导体企业开辟了另一条质量提升之路。热瞬态测试可以测量半导体结温对短脉冲的响应,还可提供对潜在制造缺陷的洞察。该技术可以揭示热传导路径中的不一致,量化其对热阻的影响并突出显示其位置。热界面材料 (TIM1) 或晶片贴装空隙或分层等问题可以在短短几分之一秒内发现,不过,像 TIM2 质量等封装外部的问题也可以用短脉冲测量。

观看此网络研讨会,了解如何使用热瞬态测试来测量半导体封装中的温度变化以及识别潜在制造缺陷。

在本次网络研讨会中了解先进的热测试和晶片贴装技术

本次网络研讨会的要点:

- 热瞬态测试在支持封装模型分析中发挥的作用

- 结构功能在缺陷识别中的应用

- 封装热质量测试用例和限值

- 将测试系统集成到半导体生产环境中的不同方法

主讲嘉宾简介

安德拉斯·瓦斯-瓦奈 (Andras Vass-Varnai)

电子和半导体产品组合开发主管

安德拉斯·瓦斯-瓦奈于布达佩斯技术与经济大学获得电子工程硕士和博士学位。他于 2007 年在 Mentor Graphics 的 MicReD 集团开始了他的职业生涯,担任应用工程师。安德拉斯拥有 10 余年的产品经理工作经验,为 DynTIM、Powertester 仪器等开发项目提供支持。在开始担任西门子电子和半导体市场产品组合开发主管之前,安德拉斯曾在韩国首尔工作,为亚洲业务活动提供支持。他目前在伊利诺伊州芝加哥工作,专注于推动美国业务增长。他的主要研究领域包括电子系统热管理、瞬态热测试和仿真的先进应用、TIM 材料表征以及大功率半导体设备可靠性测试。