Power electronics modules for vehicle propulsion play an important role in the success of automotive electrification. OEMs are looking for new technologies and innovations to get the optimal power conversion efficiency set by the performance requirements. Decisions need to integrate the variety of circuit topologies and semiconductor technologies (SiC MOSFET, Sis, etc.) to provide the appropriate voltage levels, as well as the appropriate thermal management system (might it be cold plate, double-side or liquid pin cooling). The combination of those elements will impact the vehicle’s performance during integration with regards to reliability, energy consumption, power and thermal safety. Hence, it is critical to explore the design space early in the development cycle and avoid later performance failure.

This webinar introduces how a continuous digital thread will enable you to explore design possibilities, assess performance levels from component choices to integration, and make the right decisions weighting performances, energy consumption and thermal safety.

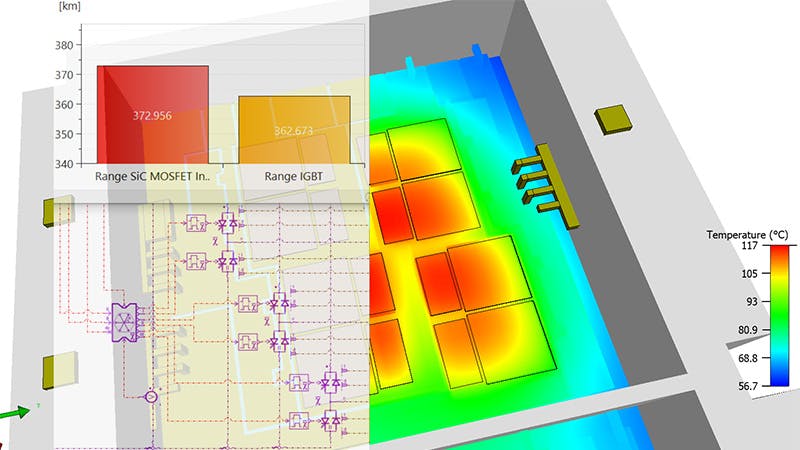

Comparing different wide-bandgap (WBG) semiconductors and inverter’s thermal management systems

In this webinar, we explain how to:

- Run thermal and electrical characterization of an electric vehicle’s inverter

- Integrate Reduced Order Models of the inverter into integrated vehicle simulation platform

- Assess the impact of different semiconductors, inverter cooling system, voltage levels on vehicle performance

About the speakers

Meet the Speakers

Byron Blackmore

Product Manager

Byron is a Product Manager for the Simcenter Flotherm product line at Siemens Digital Industries Software. Byron received a bachelor’s degree in Mechanical Engineering from the Technical University of Nova Scotia in 1998 and a Master’s degree from the University of Alberta in 2000.

Romain Nicolas

Business Developer

Romain is responsible for system simulation activities in the heavy equipment sector. He started his career in 2011 as control systems engineer in the Volvo AB Group. There, he developed a platform for control algorithms verification, led several projects as system responsible, and worked as a software developer using Agile methodology. He has a Mechanical Engineering degree from ESTACA Paris and an MSc from IFP School.