A revolution is transforming the automotive industry. Powerful digital technologies are driving demand for autonomous transport solutions, and they are disrupting existing approaches to building cars. Smart, connected vehicles powered by AI represent a challenge and an opportunity for automakers.

Engineering time for robotic operations can be reduced by up to 80% when integrating the new software controller from Realtime Robotics and Tecnomatix Process Simulate software from Siemens. Join this webinar to discover how to simplify robot programming tasks in automotive manufacturing. Learn how engineers can now author, reuse, validate and optimize manufacturing process sequences with fully kinematic 3D models.

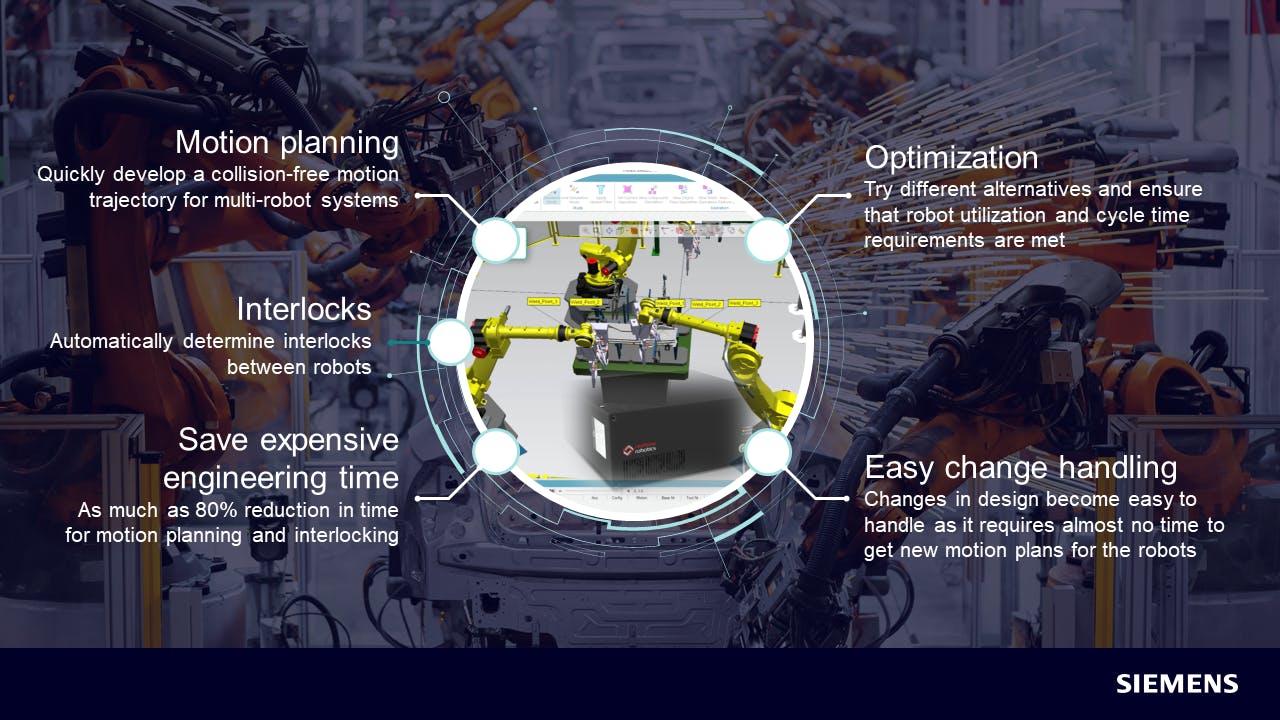

Reduce time spent motion planning and interlocking

Developing collision free motion parts for each robot while minimizing cycle times is a challenge. Design changes can have a domino effect. Realtime robotics, also known as RTR, automatically creates motion plans in real time. Robot programming tasks can be simplified with fully automated interlocking, which reduces the size of interference zones and the required space the robots will occupy as they move through their planned motion paths.

Automatically determine interlocks between robots

Interlocks between robots are identified and resolved on the fly by the RTR component. We have seen that about 70%-80% of engineering time can be saved by using this technology. Changes are easy to handle as the user doesn’t need to reprogram the motion each time a change occurs. Realtime Robotics RapidPlan Software choreographs the robots movements.

Simulate robot motions and validate collision-free movement with RTR Rapidplan

Tecnomatix robotics and automation simulation solutions give you the power to simulate complete manufacturing cells and systems. This allows you to design and validate collision-free robotic paths and optimize their motion and cycle times, using both time-based and event-based simulation methods.

In this webinar, Siemens highlights robotics solutions that address multiple levels of robot simulation and workstation development to bring automation systems online much faster with fewer errors.

Poznaj naszego eksperta

Yuval Heller

Manufacturing Product Management

Yuval has 24 years of experience in CAx. He joined Siemens in 2007 as a product manager for Tecnomatix Process Simulate, eventually taking on the role of director. Currently, Yuval manages a team responsible for the Tecnomatix Process Simulate and Process Designer product lines and heads innovation for cloud-based simulation solutions within the digital manufacturing business segment.