Consumer desire, changing governmental regulations, and technology innovations are just some factors accelerating the progress of vehicle electrification. Electric vehicles (EVs) have also become a catalyst for new players to enter this space. Subsequently, they're disrupting the traditional landscape, pressuring automotive OEMs and suppliers to expand their current product portfolios. And whether you are an established OEM, supplier, or startup, efficient and flexible production systems are a top priority in this competitive new market.

Watch the webinar to discover how an end-to-end digitalization approach to manufacturing and the development of a digital twin for production can help automotive manufacturers engineer, launch, maintain and optimize the complex manufacturing systems of the future.

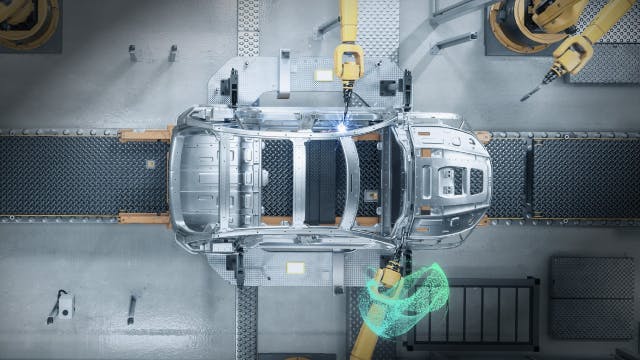

Leverage a digital twin for efficient production to optimize complex systems

To fully leverage the value of a digital twin, our customers need solutions that can connect to real production and provide meaningful feedback to any point of the connected digital thread. The digital threads offered by Siemens - software and systems engineering, accelerated product development, smart manufacturing, Internet of things (IoT), and analytics - play a significant role in supporting the transportation revolution. By adopting an end-to-end digitalization approach to manufacturing and developing a digital twin for production, automotive manufacturers can engineer, launch, maintain and optimize the complex manufacturing systems of the future.

Utilize planning and simulation information to reduce production ramp-up

Advancements in technology and changes in consumer demands are driving the “Factory of the Future.” The factory of the future is intended to enhance production by improving in three main dimensions:

- Plant structure containing a multidirectional layout supported by driverless transportation systems

- A modular line setup that can be interchanged

- Sustainable production that’s energy efficient

And by utilizing a digital twin of production, OEMs and suppliers can rehearse the launch of a new product digitally using simulation before launching it in the factory. The actionable insights gained through the digitalization of manufacturing prevent expensive errors, eliminate time-consuming rework, and produce first-time quality parts at launch and throughout the entire product lifecycle.

발표자 소개

Nand Kochhar

Vice President of Automotive & Transportation

Nand Kochhar is the vice president of Automotive and Transportation Industry Strategy for Siemens Digital Industries Software. He joined Siemens in 2020 after nearly 30 years with Ford Motor Company, where he most recently served as Global Safety Systems Chief Engineer. He also served as Executive Technical Leader, CAE, and a member of Ford’s Technology Advisory Board. Kochhar’s tenure at Ford also included executive engineering leadership across various disciplines, including product development, manufacturing, digitalization, simulation technology development, and implementation.

Todd Bengtsson

Director Automotive Manufacturing Engineering Solutions

Todd Bengtsson joined Siemens Digital Industries Software after working for 18 years in the automotive industry. Since joining in 2000, Bengtsson has focused on developing and implementing best practices and solutions for manufacturing companies.

From 2001 to 2005, he served as the GM Manufacturing Global Solution Architect and, while in this role, earned the CIO Award for the Global deployment of Tecnomatix Process Planner for Manufacturing. He continues to support manufacturing OEMs and suppliers as they evaluate and implement solutions from Siemens Digital Industries Software.