In this webinar, you will learn how digital twins can help jet engine and gas turbine manufacturers model the most complex physics faster than ever before.

Aircraft engine designers are facing stricter environmental and regulatory constraints and a push for new, greener fuels which require innovative combustion design concepts. To meet ever shorter development timelines, engineers need to leverage simulation – now more than ever – to iterate quickly through novel design concepts and across different teams.

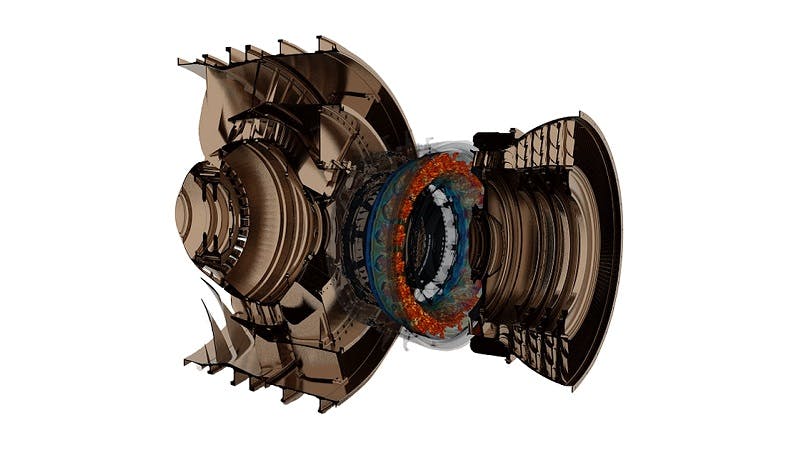

Create digital twins to predict jet engine emissions

To effectively tackle design complexities and mitigate risks of failures, aircraft engine engineers need tools that enable an integrated approach that brings simulation and physical testing together. This webinar will share how digital twins enable you to predict jet engine emissions during the design phase. You’ll see how this approach to aircraft engine performance engineering results in lower emissions, shorter development time and reduced risks and costs.

Improve aircraft engine efficiency

Learn how to:

- Model the physical behavior of complex phenomena in the core of the gas turbine: structural, fluid and heat transfer, systems design, material design

- Increase productivity in each phase of the design, from component level to whole engine and from low- to high-fidelity representations

- Adopt a design space exploration approach to find better designs that traditional workflows and toolsets can’t achieve

- Break down silos in your organization to achieve integration between disciplines, seamless workflows and data traceability

Jet engine combustion: Honeywell use case

To improve the turnaround time and accuracy of the reacting large eddy simulations (LES) needed to support design iteration, aero-engine manufacturers have to look at enhancing and extending their simulation methodologies, incorporating accurate and flexible combustion models, fast and scalable solvers and automated multi-timescale workflows.

This webinar explores jet engine combustion with a Honeywell use case. You will see, based on combustor geometries:

- Accurate prediction of emissions such as NOx, CO, unburned hydrocarbons and soot

- Improved time to solution for reacting LES simulations

- Component life prediction through the addition of multi-time scale conjugate heat transfer

Hear from jet engine performance engineering experts:

Erik Munktell, Simcenter Solution Manager for Aircraft Engine, Siemens Digital Industries Software

Megan Karalus, Solution Consultant, Siemens Digital Industries Software