The executable digital twin (xDT) is a self-contained smart, connected virtual representation of a physical asset that models its behaviors and combines them with physical data to provide augmented information.

Watch this webinar and learn to:

- Build full fidelity real-time models used for operations insight

- Use the full-fidelity model to create virtual sensors capable of using operational data

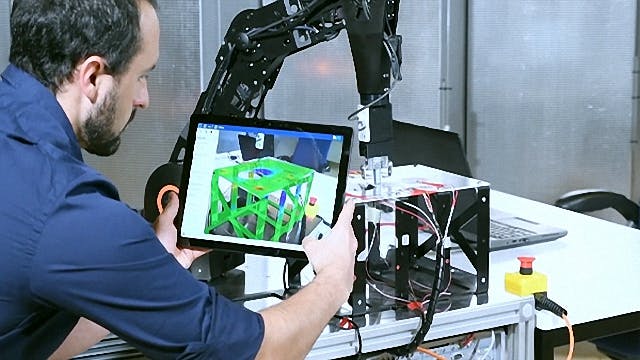

- Deploy xDTs on different industrial applications like a robotic arm, district water systems, and other machines

The executable digital twin can self-update and calibrate to reflect performance changes in the physical system as it evolves during the lifecycle.

The executable digital twin improves the flow of data

The executable digital twin (xDT) eliminates the barriers preventing simulation information from flowing across the product lifecycle.

With newfound access to high-fidelity design information during operations, plant operators and facilities gain valuable insights into machine operation and status.

Watch this webinar and discover how digital twins can be facilitated beyond product engineering to support manufacturing decisions.

Machine builders can improve energy efficiency, increase throughput, enhance quality, and reduce waste by leveraging the executable digital twin across the design, production, and service phases.

The true value of the executable digital twin

The executable digital twin (xDT) can be deployed throughout the entire product lifecycle, which creates a major shift in how models are used in design, manufacturing and operation.

Once created, the xDT can be used for a range of purposes:

- Model-based system testing (XiL)

- Smart virtual sensing

- In-service diagnosis and analysis

- Production process optimization

By using simulation modeling to watch real-time operations, machine builders and equipment manufacturers can make more informed decisions.

À propos des intervenants

Leoluca Scurria

Product Manager

Leoluca is a product manager for Simcenter 3D Smart Virtual Sensing, which provides customers with a solution combining the best of simulation and physical measurement. This technology is one of the key enablers for executable digital twins. Leoluca has been a key contributor in defining the strategy to bring digital twins across the entire product lifecycle. He holds a BSc and MSc in Mechanical Engineering from the University of Pisa in Italy and a Ph.D. on high-fidelity numerical modelling and model order reduction.

Richard Merrett

Technical Marketing Engineer

Richard works within the product management team for Simcenter System Simulation and focuses his research on executable digital twins for the plant and process and the energy and utilities industries. With more than 8 years’ experience in fluid analysis, he has constructed and tested various experimental facilities. He has also published multiple papers on simulation and physical testing – a number of which have one awards at prestigious events. Richard joined Siemens in July 2017 after earning his Masters in Mechanical Engineering at Brunel University London where he specialized in thermo-fluids.