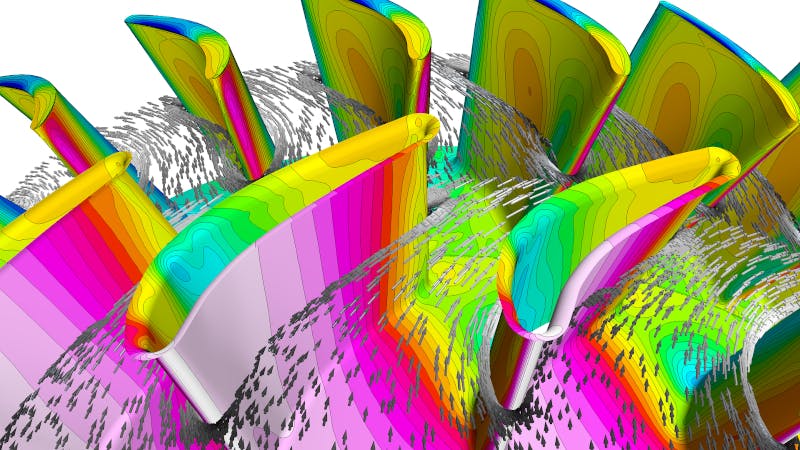

In this webinar, hear how B&B-AGEMA use sophisticated simulation tools to design efficient steam turbine blades. By combining multi-physics simulation and automated design exploration, they can design innovative blade shapes that achieve the required turbine performance and emission goals. Learn more about the challenges facing the power generation industry, and how simulation is key to successful designs in a changing energy market.

Learn about the role of simulation in turbine blade design and optimization

Watch now to find out:

- The role that multi-physics simulation plays in multiple aspects of turbine blade design and optimization

- B&B-AGEMA’s process chain for designing highly efficient steam turbine airfoils, combining 1D, 2D and 3D simulation

- The benefits of including automated design exploration at all stages of the turbine design process

This webinar will be of interest to anyone working on turbine blade design, or looking to learn more about design optimization

The design processes described in the webinar can be applied to a wide range of applications, including steam turbines, gas turbines and aircraft engines. Engineers and designers working on rotating machinery and power generation will find the results particularly useful. It will also be of interest to users looking for more information on combining NX, Simcenter STAR-CCM+ and HEEDS.

Case study: B&B-AGEMA use simulation tools to create a digital test rig

In this video, Rene Braun discusses B&B-AGEMA’s use of Siemens software, and how they use it to create a digital test rig for turbine design. This virtual approach enables them to rapidly investigate multiple design variants and operating conditions before any physical prototype is built or tested.

A complete solution for gas turbine simulation and performance prediction

We provide a complete portfolio of solutions for gas turbine simulation and performance prediction. Our software enables you to explore turbine performance digitally, reduce testing time and give confidence in designs from early in the design cycle. Using Simcenter, engineering teams can build digital test rigs and virtually optimize turbines for all critical performance areas:

- Aerodynamics & heat transfer

- Combustion

- Reliability & robustness

- System simulation

Hear from our expert speakers on their experience of using simulation tools for blade design

Conoce al invitado

Chad Custer

Product Manager, Turbomachinery