Increasing semiconductor content is an emerging trend across consumer electronics, automotive and aerospace industries. The latest packaging technologies integrate increasingly high computing power in a single package, creating thermal and mechanical design challenges at both the package and PCB board levels.

Power conversion components, such as electric traction applications, are changing too. They switch increasing amounts of power while maintaining the same package footprints. Thermal, shock and vibration-related reliability of the PCB or the component is concerning.

Watch this webinar to see how Siemens’ simulation software works seamlessly in the ECAD-MCAD flow to increase early design fidelity and innovate at a lower cost.

How Siemens' ECAD-MCAD integration streamlines electronics design

Siemens solutions combine electrical and mechanical design domains into one seamless flow. Mechanical designers can import board design data directly into design software to run quick yet accurate simulations to verify the feasibility of a design at an early stage, eliminating the need for physical prototyping.

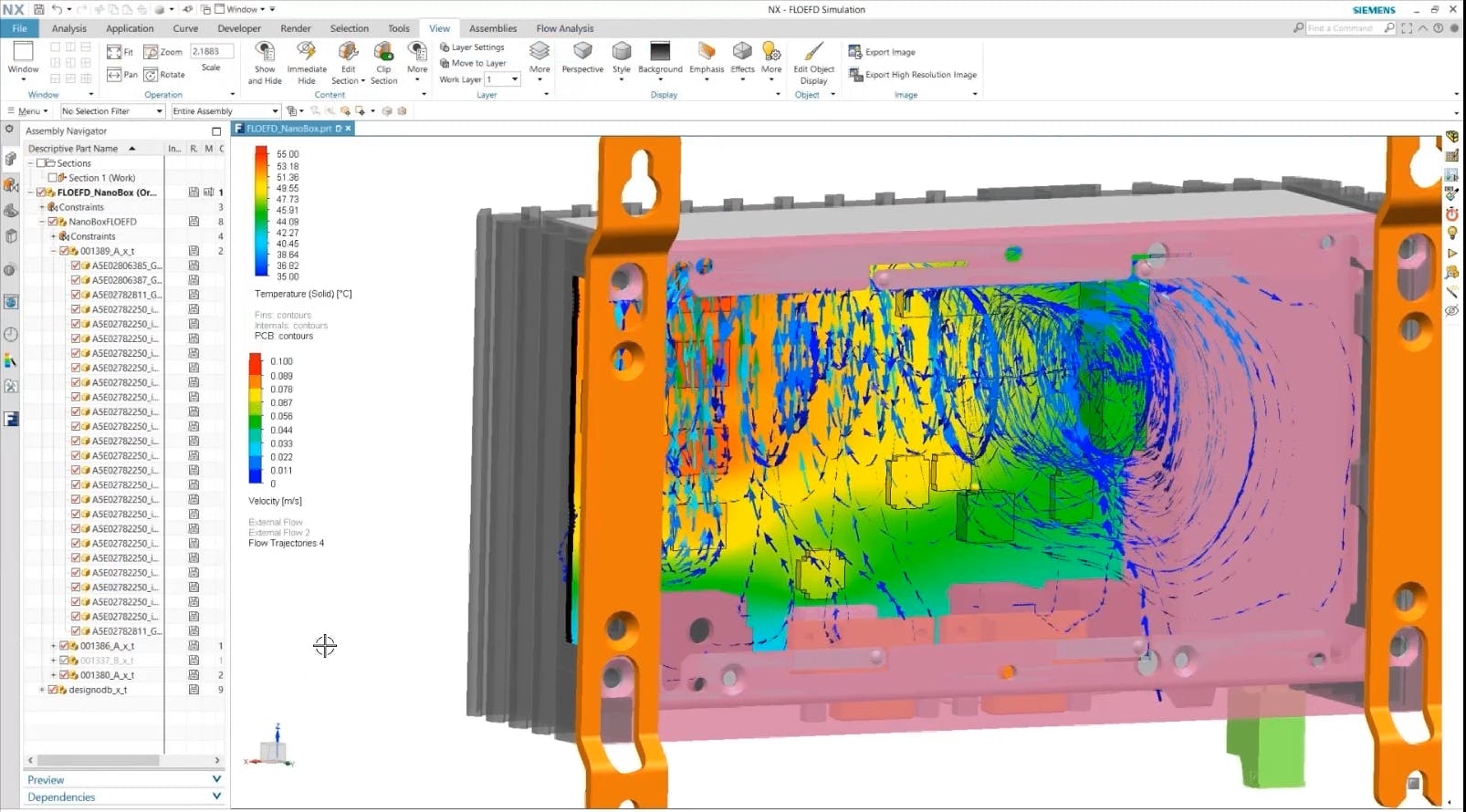

This webinar demonstrates how to import ECAD data into the mechanical environment and use simulation tools to support thermal, structural, and modal analysis of the board or subsystem. Watch a test-based approach that can calibrate the thermal model of selected high-power components while also estimating the power cycling lifetime.

Achieving high-quality electronics design with advanced simulation and testing tools

In this on-demand webinar, you'll learn how:

- Electrical and mechanical engineers can work together to validate early designs virtually

- Designers can perform simple yet accurate CFD analysis of electronic systems

- To perform structural and modal analysis of PCB designs

- Testing can further increase the accuracy of modeling and help calibrate material parameters

Discover how a seamless ECAD-MCAD flow increases early design fidelity and allows for innovation in less time at a lower cost.

Key benefits of integrated ECAD-MCAD simulation tools for electronics design

The design-to-analysis process using Siemens’ advanced simulation and testing tool suite allows companies to achieve high-quality electronics design and offers these advantages:

- Seamless ECAD-MCAD data transfer

- Users can model the complexity with high fidelity using fewer clicks

- Benefit from an automated hex-dominant mesher

- Gain access to a variety of solution types under a streamlined simulation file

Siemens NX with Simcenter FLOEFD for thermal analysis and Simcenter 3D for structural analysis

Simcenter FLOEFD is a CAD-embedded computational fluid dynamics (CFD) tool for mechanical-assisted design (MCAD) solutions, including Siemens NX, Solid Edge, CATIA v5 and Creo.

Simcenter 3D is a structural analysis tool designers use to understand how a component or product assembly reacts under stress or vibration. Simcenter provides structural analysis software to simulate various applications within a single user environment.

Meet the speakers

Tim Brodovsky

Application Specialist

Tim Brodovsky is an Application Specialist for thermal analysis software at Siemens DI SW in Portland, Oregon. Tim has 10 years of experience in thermal and airflow in electronics cooling and has expertise in Simcenter Flotherm. He has also worked with Simcenter MicReD thermal transient testing hardware along with Simcenter FLOEFD. Tim holds an MS Mechanical Engineering degree from Portland State University.

Valeria Aucapina

Presales Solutions Consultant

Valeria was born and raised in New York City where she studied Mechanical Engineering and recently relocated to Boulder County to be closer to mountains! Valeria has 5 years of industry experience analyzing static and rotating jet engine hardware at Pratt & Whitney and is currently focusing on structural analysis of turbomachinery and electronics in her role at Siemens DI SW. Valeria is passionate about helping to develop and implement analysis processes that empower structures engineers to focus on the design exploration aspect of engineering by leveraging Siemens Software to automate any repetitive parts of their work (i.e. model creation). Valeria is very lucky to support this mission as a part of Siemens DI SW where she is helping companies to accomplish their process improvement goals by making use of Siemens’ integrated workflow approach.