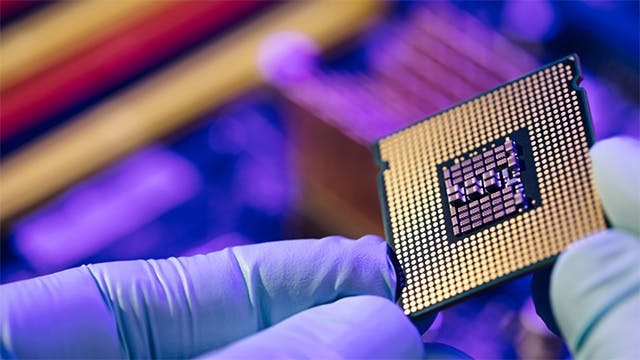

One of the main difficulties currently facing our industry is the customer's expectations, meeting a higher criterion for semiconductor quality. Using legacy processes makes this endeavor formidable. However, implementation of a digital transformation, that includes closed-loop strategy, can streamline development, boost productivity and maintain quality.

In this upcoming webinar, Siemens specialists will discuss:

- Why closed-loop quality management must be part of your digital transformation strategy

- Aligned workflows for quality to promote collaboration between teams

- How a PLM-native QMS ensures quality from the start, saving time and money

Register for this upcoming webinar to find out how a closed-loop approach has advantages.

Understanding the challenges of semiconductor quality management

The semiconductor industry is experiencing rapid evolution on a global scale. Shifting market demand, increasing competitive pressures and resource constraints have illuminated existing weaknesses and deficits within semiconductor manufacturing. Continuous improvement of your core processes is the only viable option in this unpredictable, changing market. Without a comprehensive digital transformation, including a closed-loop methodology, the quality of the final product may take multiple iterations, take longer to produce, cost more and be riddled with defects. Frustrated consumers will look elsewhere for their electronic and/or electronic component needs, causing businesses to lag behind the competition.

The benefits of harmonizing semiconductor quality across the product lifecycle

Adjusting to complex, dynamic integrated circuit (IC) markets requires a closed-loop quality strategy. With a closed-loop quality management approach, you can directly:

- Employ PLM - QMS solutions to streamline your value chain to deliver increasingly complex goods.

- Synchronize the management of semiconductor quality over the whole product lifecycle, from conception to delivery.

- Use QMS and PLM tools in a single collaborative platform to create high-quality devices

- Exceed targets throughout manufacturing, pleasing consumers with reliable and high-quality products.

- Manage data easily between domains so teams can design products properly the first time, enhance NPIs, save costs, and innovate for a competitive advantage.

Harnessing the power of QMS and PLM in semiconductor manufacturing

Quality management systems address nonconformity, complaints, root-cause investigation and risk minimization. Siemens Closed-Loop quality management system meets industrial standards. Maintain industry-leading regulatory compliance, quality and operational efficiency while meeting all criteria and offering our clients an edge.

PLM maintains all product data, including bill of materials (BOMs), revision history, and change management. Siemens PLM, a 3D software development toolkit, provides modeling, sketching, assembly, path planning, interoperability and visualization to boost innovation, reduce expenses and decrease time spent. Important in the production of semiconductors considering their need for increased power in a reduced space.

Implementing native QMS tools on a collaborative PLM platform ensures that crucial information for revising or improving new product development is easily available.

Meet the speakers

Daniel Schmitt

Portfolio Development Executive

In Daniel's current role he supports various industries including aviation, health & life sciences, automotive and defense just to name a few. Over the last 24 years Daniel has created a unique understanding of how technology works and how it is applied on the business side. He is highly proficient in Industry 4.0, Digital Twin, Digital Factory, and Smart Manufacturing initiatives. At Siemens he supports the segment sales teams with product specific knowledge of Siemens MOM solutions including Quality, Manufacturing Engineering, Advance Planning & Scheduling and MES.

Katrin Leyh

Solution Domain Quality Manager

Katrin has earned a Master of Science degree in mechanical engineering. After her study, Katrin began her professional career in 1991 with IBS in Germany. With the implementation of production, quality and traceability management solutions IBS was a brand leader in the German-speaking market for over 30 years. Katrin worked in various roles including sales, customer relations and product management. Following the full integration of IBS into Siemens in 2016, Katrin has been responsible for global business development for the Siemens sales and services organization in quality management software. Today, Katrin is the Solution Domain Manager for Digital Manufacturing Quality at Siemens Digital Industries Software.

Valentina Lupo

Solution Domain Expert for Quality

Valentina is a Quality Solution Domain Expert for Digital Manufacturing at the Siemens Digital Industries Software. She started her journey in Siemens four years ago as Industry manager for Discrete Manufacturing in Manufacturing Operations Management (MOM). Before joining Siemens, she held different positions in Quality Management and R&D in Italy and Poland, for domestic appliances companies. She also covered a Project Management position in Automotive Tier-supplier company. Valentina holds a master’s degree in mechanical engineering from the Polytechnic of Bari.