The process of manufacturing semiconductors is a mystery to most people, yet we rely on it every day to communicate, to perform our jobs, for entertainment, to survive. The process of making more than 1 trillion semiconductors per year depends on sophisticated equipment operating with astonishing precision and reliability. Undoubtedly designing this sophisticated equipment is highly challenging, largely because of the complex multiphysics involved, high precision required, and the importance of reliable operation.

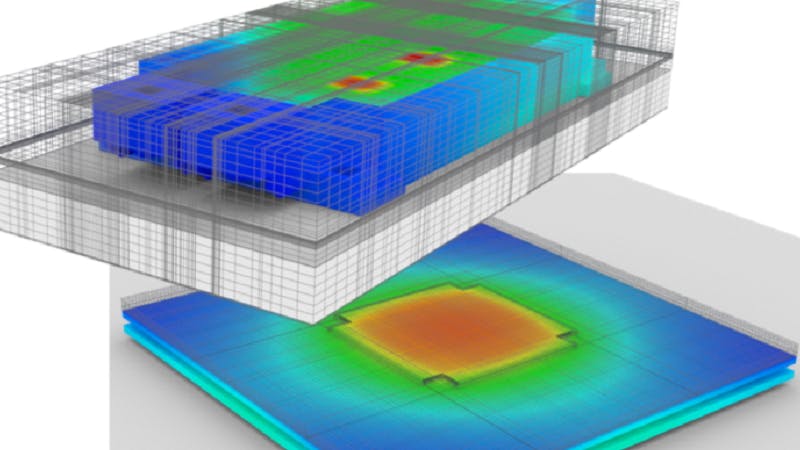

This on-demand webinar will explain how simulation is used by semiconductor equipment manufacturers around the world to design their most sophisticated equipment. We will explore key multiphysics processes along with ways simulation is used to understand and leverage these processes. These processes range from fluid flow to heat transfer, electrochemistry, reactions, and plasma. The attendee will leave with an increased knowledge of the capabilities and benefits of simulation for designing semiconductor manufacturing equipment, a rapidly growing market globally.

What you will learn

- The complex challenges of designing semiconductor manufacturing equipment

- The importance of Multiphysics effects in the design of the equipment

- Benefits of using simulation throughout the design process

- Examples of companies using simulation solution from Siemens and the value they have achieved

- An expansive view of how Siemens can give you a competitive advantage

Who should watch

- Engineering Directors

- Development Managers

- Research & Development Engineers & Scientists

- Simulation Specialists

Meet the speaker

Ruben Bons

Director, Electronics & Semiconductor for the Simulation & Testing Solutions