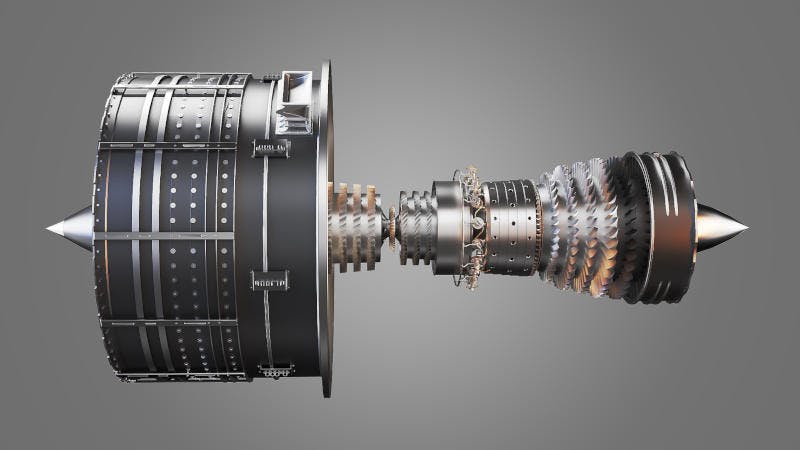

Getting the rotor dynamics of a jet engine wrong has a profound influence on operational efficiency. Longer engine start-up time may be needed, reducing throughput at already congested airports. Inflight vibrations, if exceeding a certain strength or occurring too often, have a detrimental effect on engine life and require operators to go for unplanned, costly engine repairs or even replacements.

Rotor dynamics analysis allows you to understand the influence of your design decisions on the vibration characteristics of a jet engine. This results in better products, a smoother entry into service and faster turnaround time for in-service incidents.

In this webinar, you will learn how to:

- Run synchronous and asynchronous rotor dynamics analysis in order to predict whirl frequencies and critical speeds, and detect instabilities

- Analyze rotor stability, vibration issues, and imbalance issues along the design cycle using flexible rotor dynamics simulation

- Perform sensitivity analysis to evaluate the impact of design modifications on jet engine vibrations before building an expensive physical prototype

Meet the speakers

Caroline Raick

Product Manager, Simcenter 3D

Caroline is the Product Manager for Simcenter 3D Rotor Dynamics. She focuses on areas of rotating machines and rotor dynamics. Caroline holds a diploma and PhD in Physics Engineering from Liège University (Belgium).

Sebastian Flock

Business Development Manager for Simcenter 3D Solutions

Sebastian joined Siemens Industry Software as Product Manager for Simcenter 3D Motion and now works as Business Development Manager for Simcenter 3D Solutions. Sebastian holds a Diploma and Ph.D. in Mechanical Engineering from RWTH Aachen University in Germany. His work led to the release of various publications on dynamics and multibody simulation in the context of machinery. Sebastian's working areas include multi-body dynamics, durability & NVH, drivetrains, and rotating machinery.