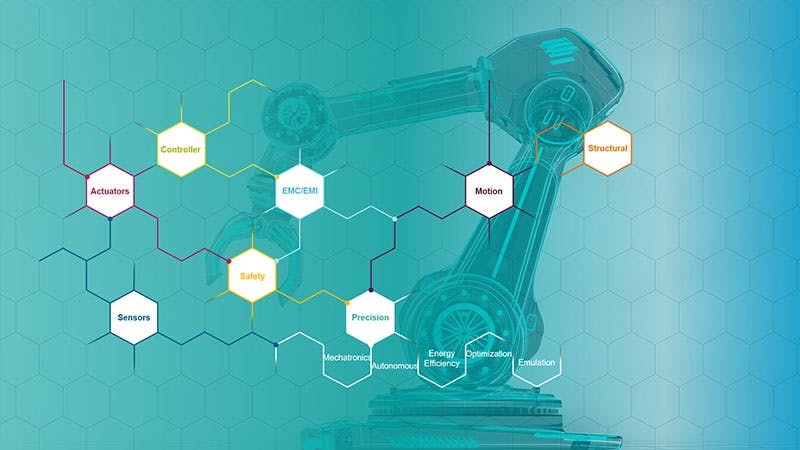

Robotics engineering constitutes several cutting-edge technologies (AI, ML, sensors, PLC, etc.) and poses unique challenges when it comes to balancing performance — reliability, scalability, safety and energy efficiency.

Relying solely on prototype testing is time-consuming and cost prohibitive. Simulation and test solutions offer several advanced capabilities to engineer futuristic robots efficiently.

In this educational webinar robotics experts present robotics engineering best practices using a cross-domain solution. You will learn to:

- Evaluate sizing of a robotic actuator to real payload and validate control logics with PLCs in SiL/HiL

- Validate the work envelope and the performance of robot manipulators in potential working environments

- Use simulation, testing and IoT to perform asset health monitoring

- Achieve stricter targets for performance, reliability, safety and efficiency

Robot integration and commissioning

Robot integration and commissioning is the crucial and final stage of development. Any control logic integration issues or automation bugs during robot integration or commissioning is expensive to resolve. System designers, builders, integrators, suppliers and end-users rely on virtual modelling and testing tools to handle robotics’ complexity.

Discovering robot’s performance insights earlier and before prototyping is possible by adopting Digital twin approach. In this webinar, you will learn how Investigating sub-systems interactions from the early design phases eliminates system or performance issues during robot integration and commissioning.

Robot structural analysis

Robot and robotic systems lifting heavy objects is subjected to mechanical deformation. Robot structural analysis permits engineers to evaluate the strain on the robotics arm, joints and bearings under real operating loads virtually.

From analyzing the kinematics and dynamics of a robotic manipulator to improving its energetic performance or even developing a modular system with an inexhaustible list of add-ons, multi-physics CAE simulation and testing tools provide cost-effective solutions to achieve targeted results.

In this webinar, we illustrate how simulation helps robotics engineering companies in structural, kinematics, thermal and durability challenges.

Robot accuracy and repeatability

Robot accuracy and repeatability are directly linked to the vibration and operational dynamics of the integrated sub-system and its components. Any undesired vibration (arising from gear backlash, sensor resolution, control system or joint misalignment) during operation limits the precision of robots. Improving the high pose repeatability of industrial robots without increasing the cost is a major research field in robotics engineering. This webinar provides viable solutions to address robot’s precision and repeatability problems.