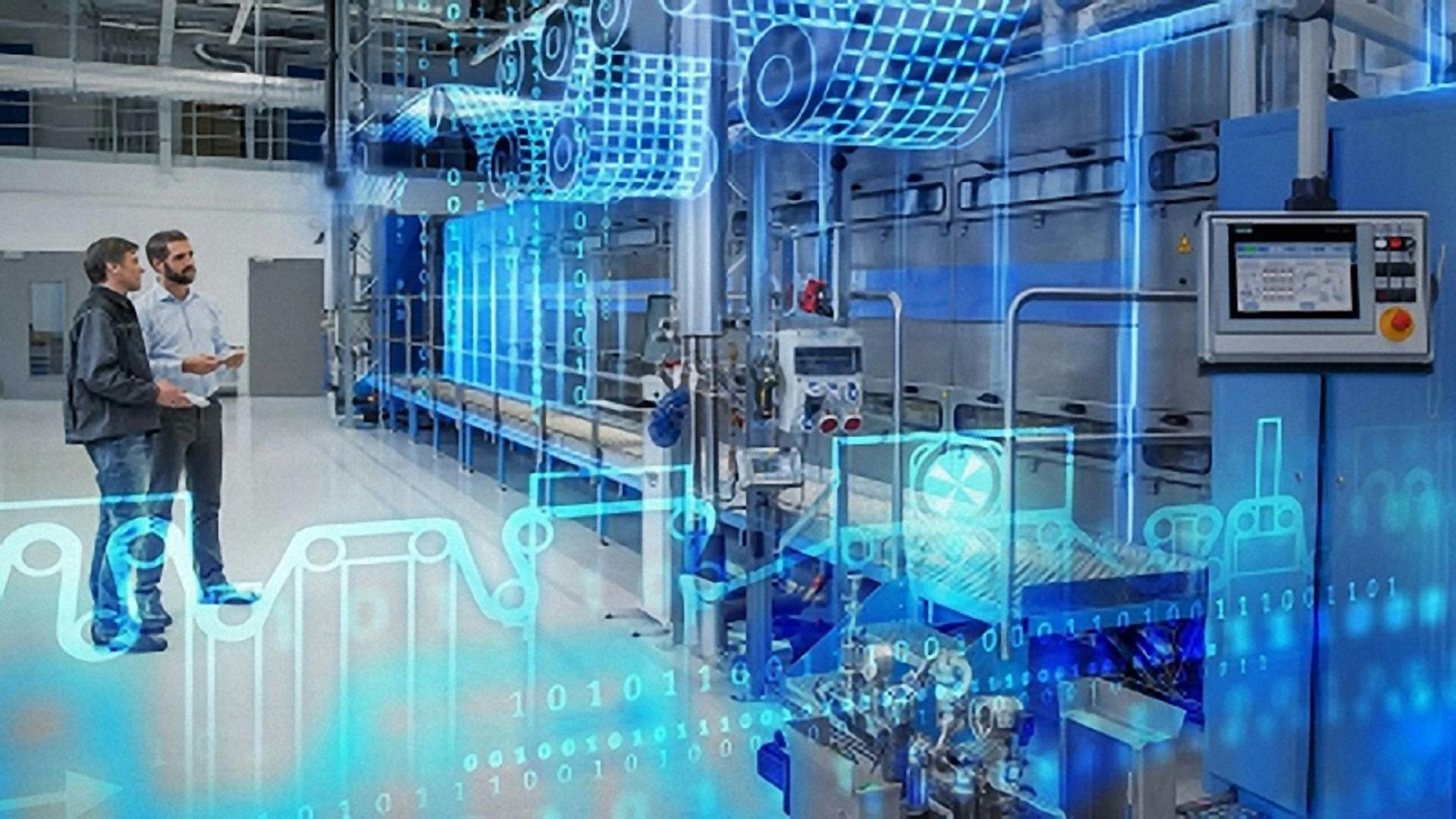

In this session we take the digital twin to the factory floor. How do we connect the Digital Twin to automation? How can you commission a machine without impacting or stopping the production line? We will see how virtual commissioning is done by connecting the digital twin with automation code, to simulate transient behavior of multi-domain systems including hydraulics, pneumatics, electronics, thermal & mechanics of a machine and couple with the automation code (SIL) and real PLC (HIL). SACMI will come to present their project on how virtual commissioning was successfully applied. Next to this, we will also close the loop between the real machines and the digital twin. Model-Based System Testing allows combining real machine data with information from the digital twin. This provides many advantages, like for virtual sensing. Finally, we will show how a complete production plant can be optimized by using a Factory Digital Twin Model with a low code-developed application framework. Throughout the session we will share real project examples, inspiring you how Siemens technology can also benefit you.

Story line:

- Virtual commissioning

- Solution presentation

- Application Cases

- SACMI customer presentation

- Multiphysics Simulation of converting machines

- Solution presentation

- KIT Battery production customer presentation

- Closed loop validation through virtual sensing

- Solution presentation

- LifeTwin application case

- Optimize my plant!

Meet the speakers

Alex Vermeulen

Portfolio Development Simcenter TEST Solutions

Umberto Badiali

Business Development Manager, engineering services

Gian Marco

Design Engineer

Jerome Flender

Solution Manager Multiphysics Simulation

Kamal Husseini

Research Associate

Aldo Alessandro Negri

System Engineer, Technical Sales Support Professional

Guillaume Cordonatto

Solution architecture & Digitalization strategy