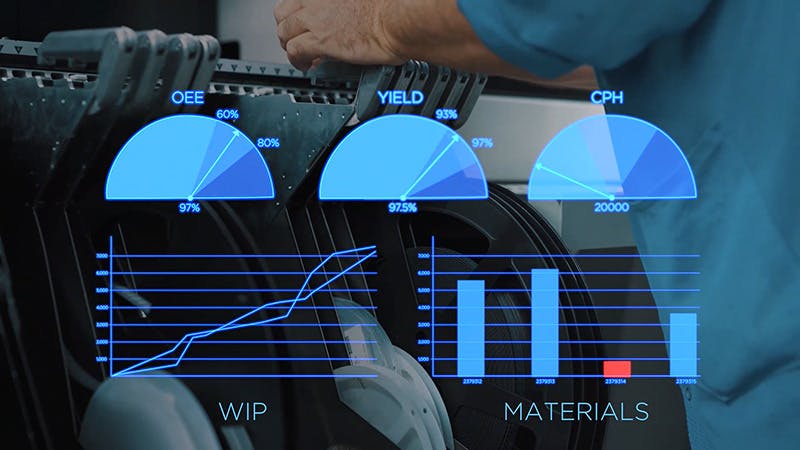

Imagine the ability to manage your material with an automated solution which takes control over all the materials in the factory. It provides full visibility of the movement of material within the factory, while tracking use of the material used on the shop floor – reducing the time needed for material replenishment almost to zero. The Material Management solution is aware of the production capacity of the lines, and provides advance notifications before existing supplies are finished.

Let’s share our experience about how Valor Material Management can help electronics manufacturers build a smarter factory today.

Material Management solution for PCB manufacturing

As the demand for quick delivery of a wide variety of electronic products accelerates, manufacturers are constantly looking for ways to boost productivity. In today’s manufacturing realm, the most frequent occurrence that impacts operational efficiency is when materials required for production can’t be found. Missing material leads to line production stoppages, as well as time- and manpower-consuming searches in the warehouse and on the shop floor.

In the webinar, we will cover how the Valor® Material Management is designed to address the many challenges facing manufacturers with regards to the control and visibility of the materials in the factory. Material Management offers clear ROI, by reducing inventory levels and material waste, while improving factory productivity and product quality.

Who is presenting:

Sagi Reuven is the Valor’s Shopfloor Business Manager. He will share his vision and drive you along this journey to Automated Material Management.

Meet the speaker

Sagi Reuven

Shopfloor Business Manager