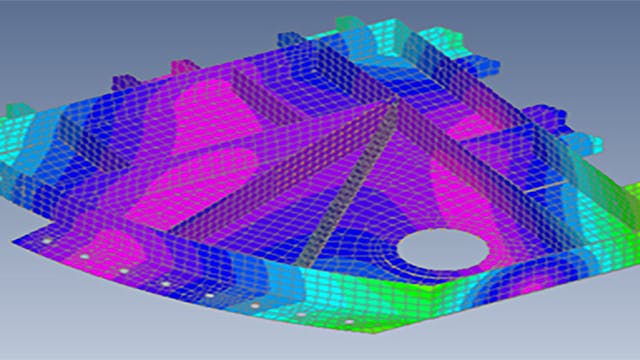

Developing a successful, effective finite element analysis (FEA) model can be a frustrating experience for design engineers. The model needs to be simple and easy to replicate while still being complex enough to provide valid test results.

This creates a problem where models are often too simplified and approximated to provide accurate analysis, or the model is too complicated for processing.

Different types of models also call for different types of mesh generation. Finally, loads need to be applied accurately to achieve accurate results.

Key Learnings

- Understand the benefits of simplifying geometry for model preparation and running analyses.

- Discover the power that comes with leveraging automated tools when extracting midsurface geometry from complex parts.

- See how using interactive tools provides quantifiable improvement to workflows when defeaturing or modifying geometry of all kinds.

- Explore how updating the thickness of shell elements allows for more iterations of thin-walled structures to be analyzed in a timely manner.

Meet the speaker

Siemens Digital Industries Software

Chip Fricke

Principal Applications Engineer Simcenter Femap