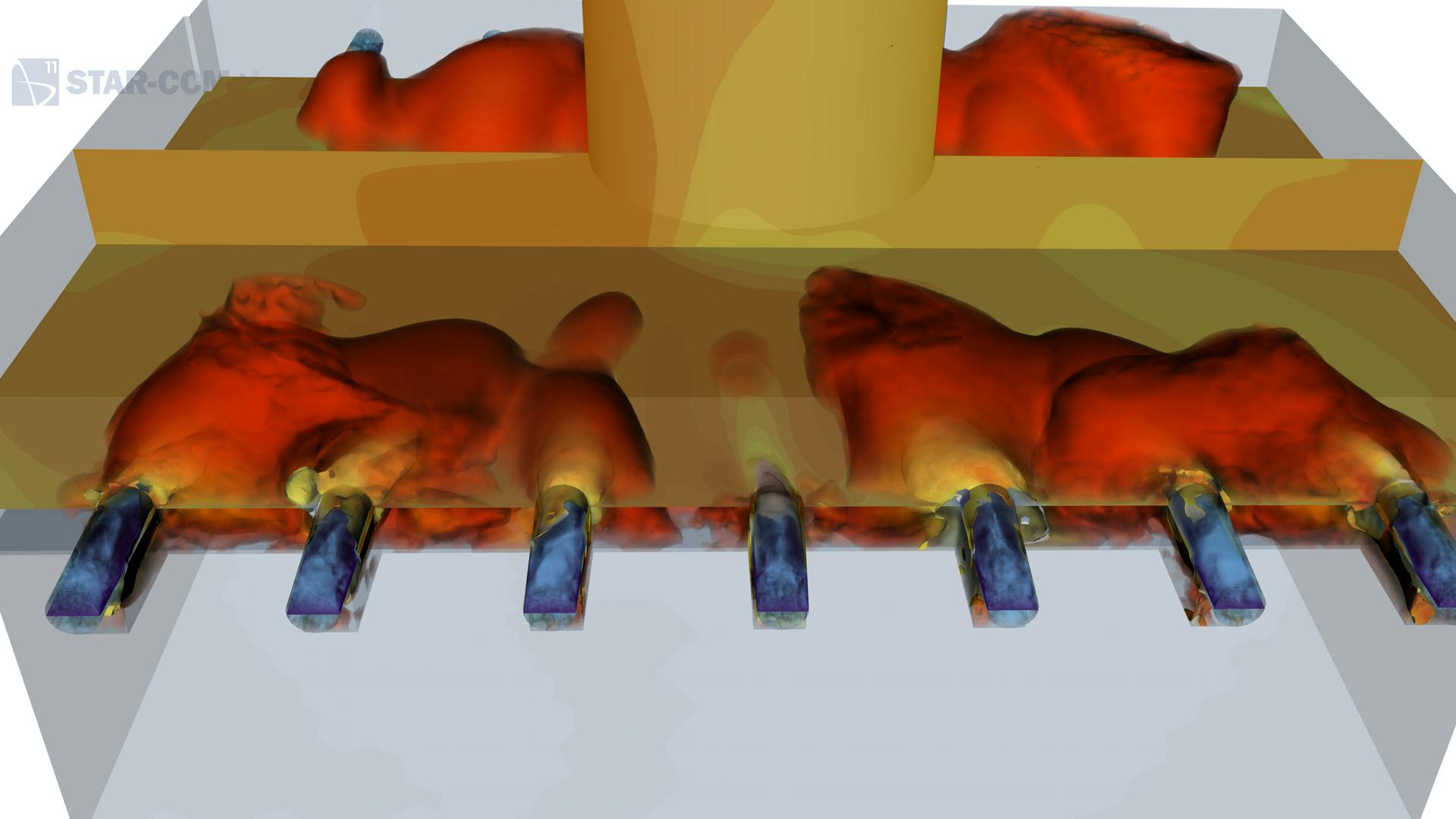

Energy consumption and pollution control are two main drivers in all combustion/high temperature processes such as those in furnaces, heaters, ovens, dryers and rotary kilns. Simulation has a large role to play in reducing energy consumption while meeting regulatory pollution-control requirements, and can significantly improve the bottom-line of the process, refining, chemical, glass and steel industries.

In this webinar, you will learn:

- How thermal and combustion engineers can benefit from using simulation to optimize operating conditions and designs

- How straightforward it is to set up geometry, a reasonable mesh and adequate physics in order perform simulations and design explorations with Simcenter STAR-CCM+®

- How the Multiphysics approach in Simcenter STAR-CCM+ can be used to address the challenges associated with:

- Combustion and pollutants

- Acoustics and flame dynamics

- Conjugate heat transfer

- Optimizing operating conditions using rigorous approaches

Who should attend:

- Thermal engineers/Furnace engineers and managers who want to troubleshoot or optimize combustion and thermal processing equipment--this event will help you understand the applicability of deploying simulation to achieve these objectives

- Combustion engineers who are already using CFD in engineering work flow--this session will demonstrate the strengths of Simcenter STAR-CCM+ meshing, workflow and the latest physics models for some of the most challenging mixing problems in the industry

Speakers:

- Dr. Zhi G. Xu, Head of Technology, Kiln Flame Systems

- Dr. Niveditha Krishnamoorthy, Technical Specialist, Combustion and Reacting Flows, Siemens PLM Software