Automotive OEMs and suppliers are moving toward fully integrated electric drive systems, often referred to as e-drives or e-axles. Apart from intense economic pressure when developing highly efficient and robust electric drives, they experience challenges concerning operational excellence, cost reduction, and time-to-market.

Electric drive systems incorporate the electric motor, transmission, power electronics, and controls into one integrated package. This requires design and engineering disciplines to cooperate closely together. As a result, manufacturers look for mechanical, electro-mechanical, electromagnetic, thermal, vibroacoustic, electric, electronic, and controls teams to work more collaboratively.

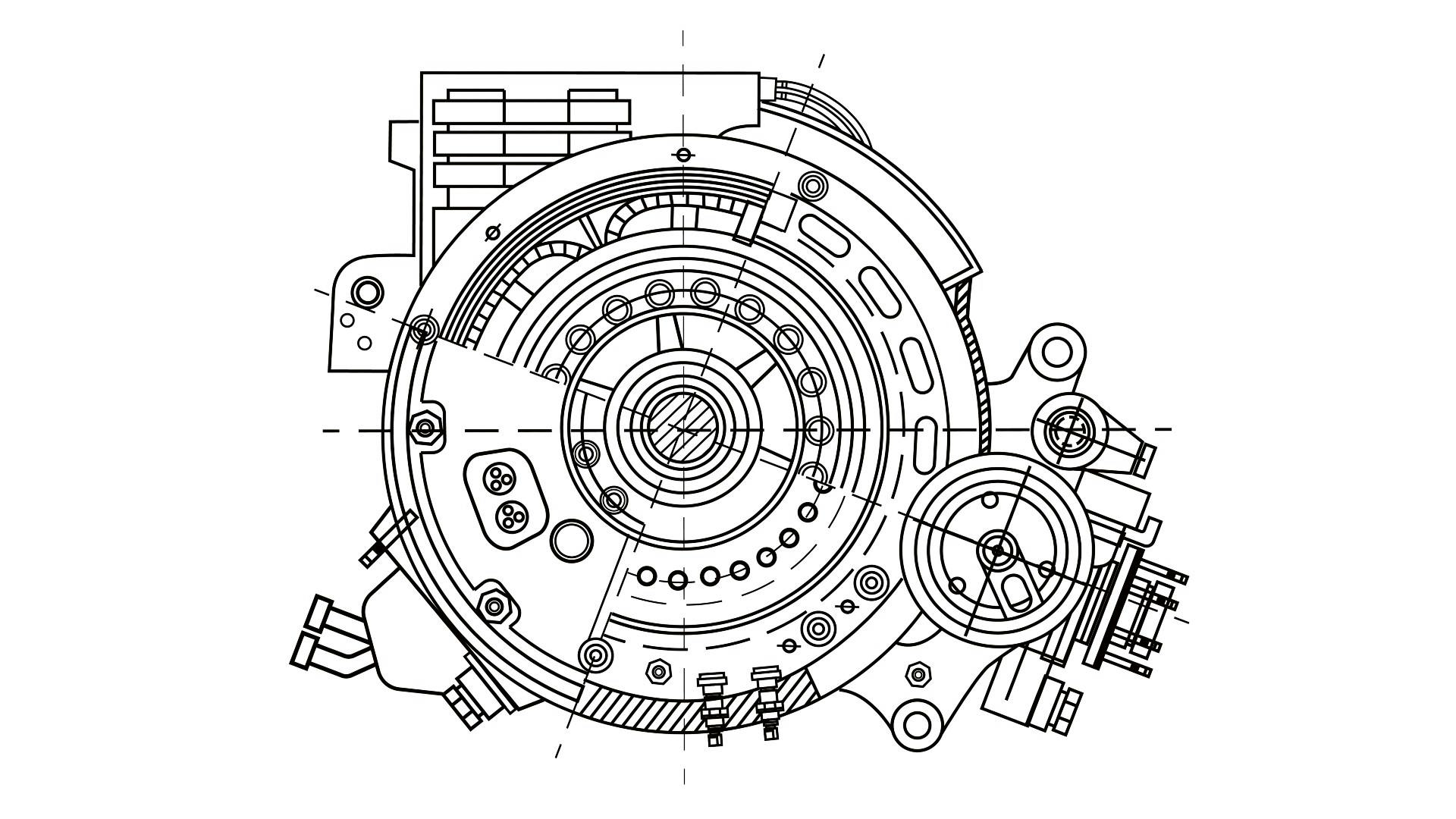

Cross-domain engineering and optimal vehicle integration of electric drivetrain components

To predict the performance of systems and systems of systems, it is critical to use a flexible, open, and scalable simulation and testing portfolio. From subsystem design to vehicle integration, the Siemens Simcenter solutions enable seamless connectivity among detailed component-level design and system simulation tools. It supports engineers during all phases of the development, from evaluating trade-offs early in the design process over component and sub-system design to final validation.

Using multi-physics simulations performed on the same model, engineers can evaluate cross-discipline performance and make final design adjustments. Combined with Simcenter multi-domain simulation solutions, this can accelerate electric drive systems development from component design, packaging, thermal, or NVH performance, and integration.

Watch the webinar and discover how to effectively manage electric drive systems engineering challenges by providing a collaborative and flexible ecosystem for systems, electromagnetic, thermal, mechanical, and acoustics engineers.

Use electric drive engineering to enable seamless collaboration across systems

- Deploy an integrated workflow for electric drive engineering

- Gain valuable insights into trading off attributes and developing the optimum design

- Rapidly re-design the electric drive and its components and reuse workflows

- Use the latest data version by staying connected to a PLM platform

Meet the speakers

Benoit Magneville

Product Manager for Simcenter Electrification

Sudhi Uppuluri

Director Automotive & Transportation Industry at Simcenter