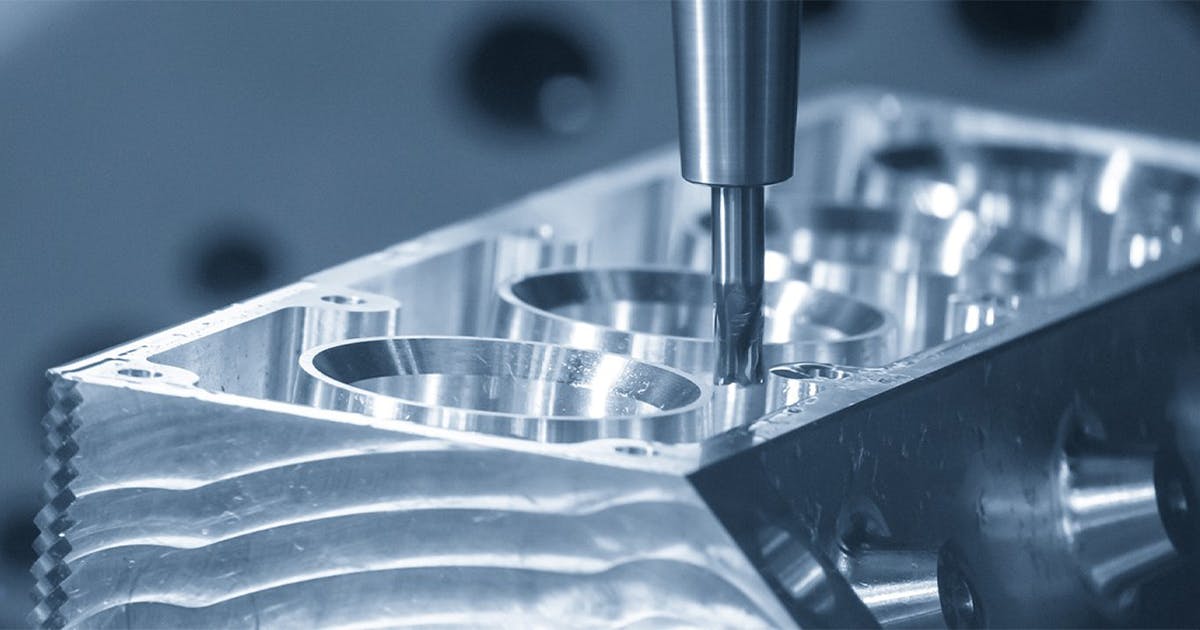

Parts and components manufacturers can efficiently and cost-effectively create today’s increasingly complex machine parts thanks to Computer-Aided Manufacturing (CAM) software.

Some manufacturers, however, still fall behind because they’re spending unnecessary hours manually programming pockets, holes, and other features on simple parts.

Smart software solutions can significantly reduce programming time by automating repetitive tasks.

Watch this on-demand webinar and find out how to make better parts faster with a comprehensive solution for CAD, CAM, CMM, robotics,

Highly automated CAM merges digital and physical processes

By leveraging highly automated CAM technology, machine builders can easily reuse proven data to automate programming and optimize machining processes to deliver consistent results.

Watch this webinar to learn how to:

- Reduce programming time by up to 90% with feature-based programming

- Speed up setup while defining optimized workpiece positions in the fixture

- Achieve desired tolerances using Product Manufacturing Information (PMI)

- Program collision-free and high-performance toolpaths using the “digital twin” of your setup

- Automatically update programs and shop documentation when the parts or fixturing design changes

The solution discussed in this webinar accelerates production, reduces waste, improves part quality, and increases production efficiency gains.

Five reasons to embrace automated CAM technology

Efficiently manufacturing today’s increasingly complex parts requires automation where it was previously not possible.

With more automation, manufacturers can:

- Accelerate production – Rising customization means producing more configurations than ever

- Differentiate – Deliver consistent results and improve quality to stand out from the competition

- Reduce waste – Connect the entire production operation from end-to-end and do away with costly errors and waste

- Improve communication –Every team has access to the same information in real-time using cloud-based systems.

- Optimize processes – Leverage machine learning to optimize machining, shorten cycle times, and improve part quality.

Watch the webinar replay to learn more about highly automated CAM.