Traction motors, which are mainly permanent magnet, have higher power densities to lightweight the powertrain. While lightweighting reduces electromagnetic and thermal masses, these machines are prone to saturation and overheating at peak loads, especially at elevated temperatures. Therefore, important to ensure proper cooling for traction motors since their intermittent drive-cycle operation, service life, permanent magnet and insulation stability are temperature-rise dependent.

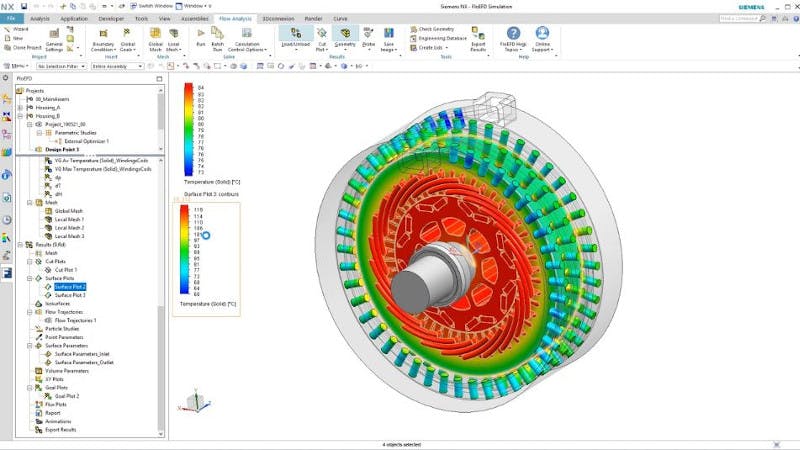

This webinar will introduce part of the Simcenter traction motor low-frequency electromagnetic-thermal CFD solution. The solution will show how to quickly set up the motor model, analyze its electromagnetic and thermal performance and electromagnetic heat-losses, and then run design optimization to improve cooling by accounting for the flow rates and the allowable pressure drop.

Design the appropriate traction motor cooling system for increased safety and reliability and maximized performance

What will you learn in this webinar?

- How traction motor low-frequency electromagnetic-thermal CFD solutions are ensuring robust designs at peak conditions.

- How to run coupled EM-thermal analysis

- How to use the appropriate tools for demagnetization analysis

- How to optimize thermal design

About the speakers

Meet the speakers

John Wanjiku

Low-frequency Electromagnetics Product Specialist

John Wanjiku joined Siemens (formerly Infolytica Corp) in December 2016, after earning his Ph.D. in Electrical and Computer Engineering majoring in electrical machines. He has over five years of experience in electric machine design and core loss measurements. His areas of interest include the application of FEA in the design of electric devices, electric drives and core losses. He is currently Low-frequency Electromagnetics Product Specialist for the Simcenter portfolio.

Mike Gruetzmacher

Technical Marketing Engineer

Mike studied Mechanical Engineering at Bochum University of Applied Sciences and worked at NIKA GmbH, Frankfurt as an Application Engineer where he worked with Simcenter FLOEFD at its early stages. He went on to work as a Project Manager for Waste Heat Recovery Systems, Küttner Energy & Environment GmbH for eight years. Mike has also recently studied Business Economics for Engineers. Mike now works in the Simcenter portfolio group at Siemens Digital Industries Software as a Technical Marketing Engineers specializing in Simcenter FLOEFD.