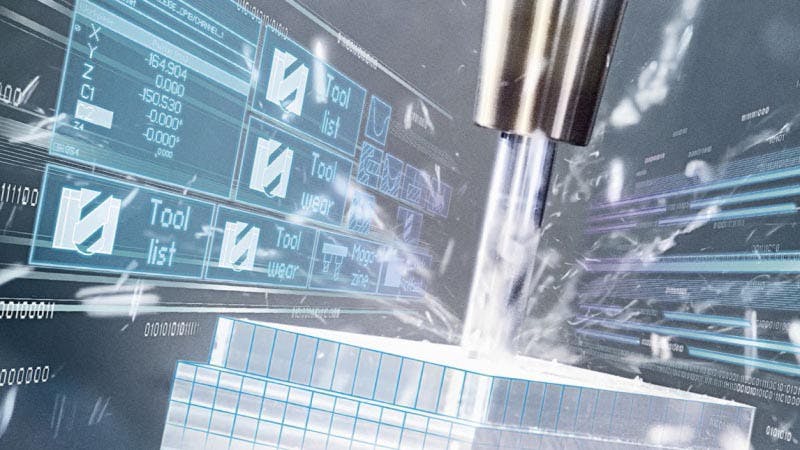

This webinar highlights the advantages of automating the part manufacturing development process, focusing on automating the Computer-Aided Design and Manufacturing (CAD/CAM) tasks.

Higher levels of automation help manufacturers, from startups to global companies, improve the overall operational efficiency, including:

- Accelerate the development of part manufacturing processes

- Capture and reuse of best-practice methods

- Rapidly create optimal toolpaths using automated, rule-based methods

Watch this webinar to learn how Siemens NX CAD/CAM software connects, automates, and accelerates end-to-end manufacturing processes, enabling manufacturers to deliver higher quality parts faster.

In this webinar about CAM automation, you will learn how to:

- Automate the creation of manufacturing assemblies to describe the entire machining setup

- Simplify the documentation of setup drawings well in advance of program availability

- Create detailed models of fixtures and work holding equipment

- Generate optimal cutting operations using the precise state of in-process workpiece (IPW)

- Output complete, associative shop documentation directly from your CAM environment

- Leverage integrated, G-code-driven machine simulation in NX CAM

Gain efficiency using one comprehensive CAM software

Prepare any CAD model and program any job using one CAM software. NX CAM provides comprehensive part model preparation and NC programming capabilities in a single system. This enables the use of consistent 3D models, data and processes to seamlessly connect planning and shop floor operations with a digital thread.

You can streamline and automate NC programming, while reducing cycle time, using powerful, application-specific tools. From 2.5-axis machining and mold manufacturing to simultaneous 5-axis milling and high-volume production, NX allows you to use one CAM software to make better parts faster.

JK Machining: Staying competitive through automation

This Michigan-based company focuses on Class 101 molds—high-production molds designed for 1 million or more cycles. Their automotive and medical customers demand high quality, tighter tolerances, timely delivery and reasonable costs.

Formerly, JK Machining used separate software systems for mold design and manufacturing. To move from design to production required multiple data transfers that introduced additional steps and errors into the process. Furthermore, it complicated the handling of inevitable and frequent design changes.

JK Machining selected NX based on several key characteristics of the software. The CAD tools of NX include powerful functions for working with customers' models. For NC programming, NX CAM’s leading-edge 5-axis and high-speed machining capabilities enabled JK to take full advantage of its advanced machine tools. With its fully integrated capabilities, NX provided automation of the entire mold development process, from design through manufacturing.