When it comes to acoustic performance, consumers hold electronic products to a high standard. Consumers expect these electronics to provide an optimal user experience and run quietly, with many considering quiet products as higher quality. Conversely, it’s not only about noise suppression. Optimizing the acoustic performance of loudspeakers and microphones is key to the perceived quality of audio products. Producing powerful, high-quality consumer goods requires advanced noise engineering and sound characterization.

Watch the webinar to understand how a combined simulation and test approach in the early design stages delivers critical acoustic performance insights and enables innovation in less time and at a lower cost.

Deliver critical acoustic performance insight and allow innovation in less time and at a lower cost

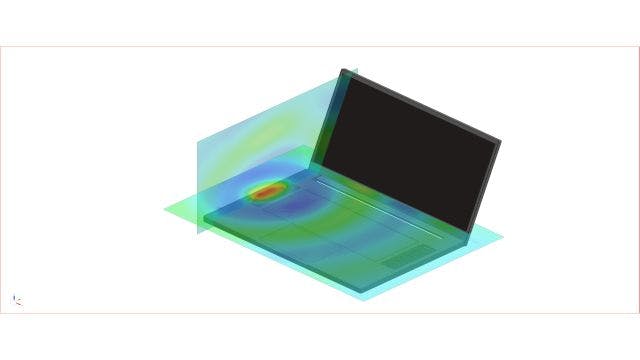

Designers of consumer electronics can also quickly evaluate multiple scenarios without expensive prototypes or delaying production. With a combination of simulation and test in early design, design teams unlock the ability to deliver critical acoustic performance insights to ensure the best product can be made at a competitive price.

Why acoustic testing is important in the early development stages for consumer electronics

Consumer electronics companies face challenges with increased complexity, new technology adoption and quick responses to emerging market trends. Miniaturization, high power density, increased cooling needs and lower cost goals add to the existing pressure to bring products to market faster. Developing leading and performant electronic products requires an innovative and adaptive engineering approach. Companies using acoustic testing in the early development stages can benchmark competitive products, pre-select components, and deliver data for use in simulation models.

Meet the speakers

Frank Demesmaeker

Business Development Manager Mechanical Industries

Frank Demesmaeker graduated in 1994 as Civil Engineer from the Katholieke Universiteit Leuven (Belgium) and started working at LMS International – now Siemens - in a technical support role for the Benelux area customers. Over the years, he has build up in-depth knowledge and practical experience in noise and vibration issues from worldwide customers, both from a technical, commercial and marketing point of view. Frank is currently helping in promoting and tuning the test applications into markets like energy, medical, consumer goods, ship, educational institutes and the broader mechanical machinery market.

Bert Van Genechten

Simcenter 3D Product Manager Acoustic Simulation

Bert Van Genechten is a product manager for acoustic simulation in the Simcenter 3D team. Bert has joined LMS International (now Siemens) in 2011 as Senior Research Engineer working on acoustic simulation technologies. In 2015, he took up the role of Project Leader in the Simcenter Engineering and Consulting Services team of Siemens focussing on NVH-related simulation and testing projects, before joining the product management team in 2021. Before joining Siemens, he obtained his MSc and PhD degrees in Mechanical Engineering from the Catholic University of Leuven.