The traditional use of electronics thermal analysis in its basic function has always been to assess whether a design will adequately ensure maximum temperatures are not exceeded. Improving a design to meet a performance goal using parametric studies and optimization techniques is widely recognized. Even assessing mission profiles using transient simulation is now more prevalent for power management studies or to generate temperature cycling insights.

How many thermal simulation-based design processes today are typically assessing the wide influence of variability from either manufacturing defects or to help quantify impacts of simulation input variations? This on-demand webinar explores the use of electronics thermal analysis combined with statistical design space exploration tools.

Evaluating variability in electronics thermal analysis inputs

Typical electronics cooling simulation studies include multiple design inputs that may be subject to variability e.g data sheet interpretation, material property variation, incorporation of engineering judgment.

Understanding how the thermal performance changes as uncertainties are quantified through statistics will result in more reliable electronics systems

Assessing manufacturing defects or variations with electronics thermal analysis and design exploration

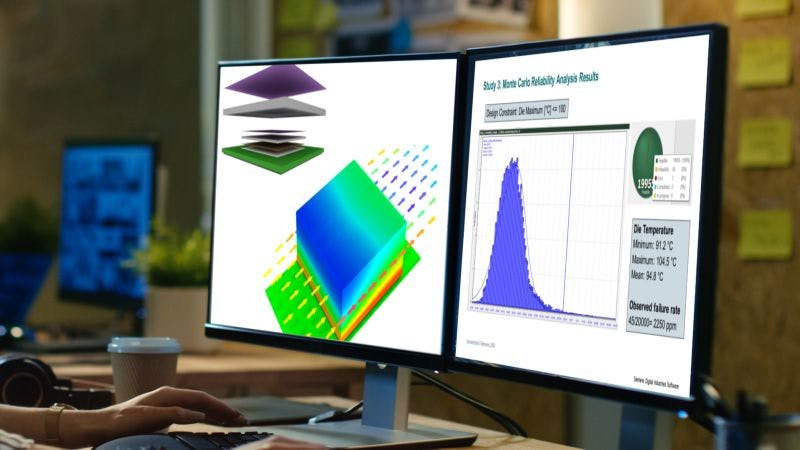

By combining electronics cooling thermal simulation with statistical approaches, engineers can more fully explore the design space. They can also apply analysis to evaluating potential impacts of certain manufacturing quality variation or defects. This on-demand presentation introduces an approach to simulation-based assessment of variations in manufacturing that can influence field reliability of an electronics product.

Studies performed shown in this presentation include Design of Experiments and Monte Carlo methods

Surrogate modeling advantages – for exploring uncertainty and variation

A 3D thermal simulation model can provide more insight if it is exercised beyond the nominal input values. Surrogate modeling provides a method to guide an electronics thermal design within the time constraints of a typical design process.

Thermal Interface Material (TIM) manufacturing defects – a heatsink package simulation example

An example is included in this recorded technical presentation looking at the impact of different sizes of TIM material defect, position and variations in thermal conductivity that then influence the operating junction temperature of a package.

Similar approaches to this example can be used to explore variation in thermal bondline performance by evaluating surface flatness, voiding, material performance and TIM degradation over lifetime due to cycling.