The field of industrial robotics has reached the next level of automation, with improved production flexibility and reduced programming time. Artificial intelligence (AI) and machine learning (ML) are technologies that enable robots to perform many tasks they could not have done before. Building, validating and deploying these technologies for advanced robotic systems remains a big challenge today.

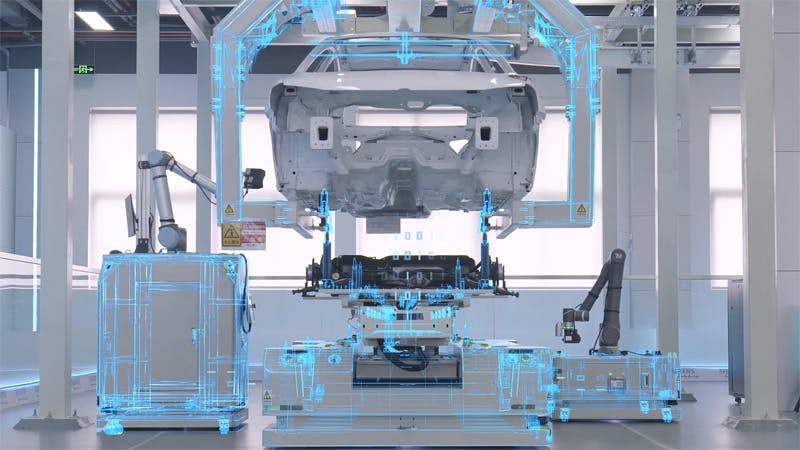

Learn how a digital twin of manufacturing, including the product design, process definition, and factory equipment, coupled with sophisticated AI hardware and software, can help ease the pains of deploying artificial intelligence and machine learning methods for advanced robotics applications.

Artificial intelligence for advanced robotics as a pillar for the future digital manufacturing engineering platform

Advanced robotics take the complexity that has grown since the inception of mass production and leverages it to develop a highly connected and efficient workflow that can meet the changing needs of a diverse landscape of high-mix production output. Many companies are already implementing advanced robotics technologies and the necessary practices to digitalize manufacturing, helping them to meet the challenges of complexity, customization, and openness, ultimately improving their timeline for new product introductions and responsiveness to market demands.

Siemens Digital Industries Software and Realtime Robotics have partnered to provide a unique, additional value to manufacturers. The use of Siemens Process Simulate software in the Tecnomatix® portfolio with Realtime’s hardware and software technology can help simplify robot programming and workcell coordination by automating motion programming with AI, well in advance of production.

Vorstellung der Referenten

Alex Greenberg

Director, Advanced Robotics Simulation

Yuval Heller

Manufacturing Product Management

Yuval hat 24 Jahre Erfahrung in CAx. Er kam 2007 als Produktmanager für Tecnomatix Process Simulate zu Siemens und übernahm später eine leitende Funktion. Derzeit leitet Yuval ein Team, das für die Produktlinien Tecnomatix Process Simulate und Process Designer zuständig ist und leitet die Innovationen im Bereich cloudbasierter Simulationslösungen innerhalb der Geschäftseinheit digitale Fertigung.

Darius Wilke

Director, European Business