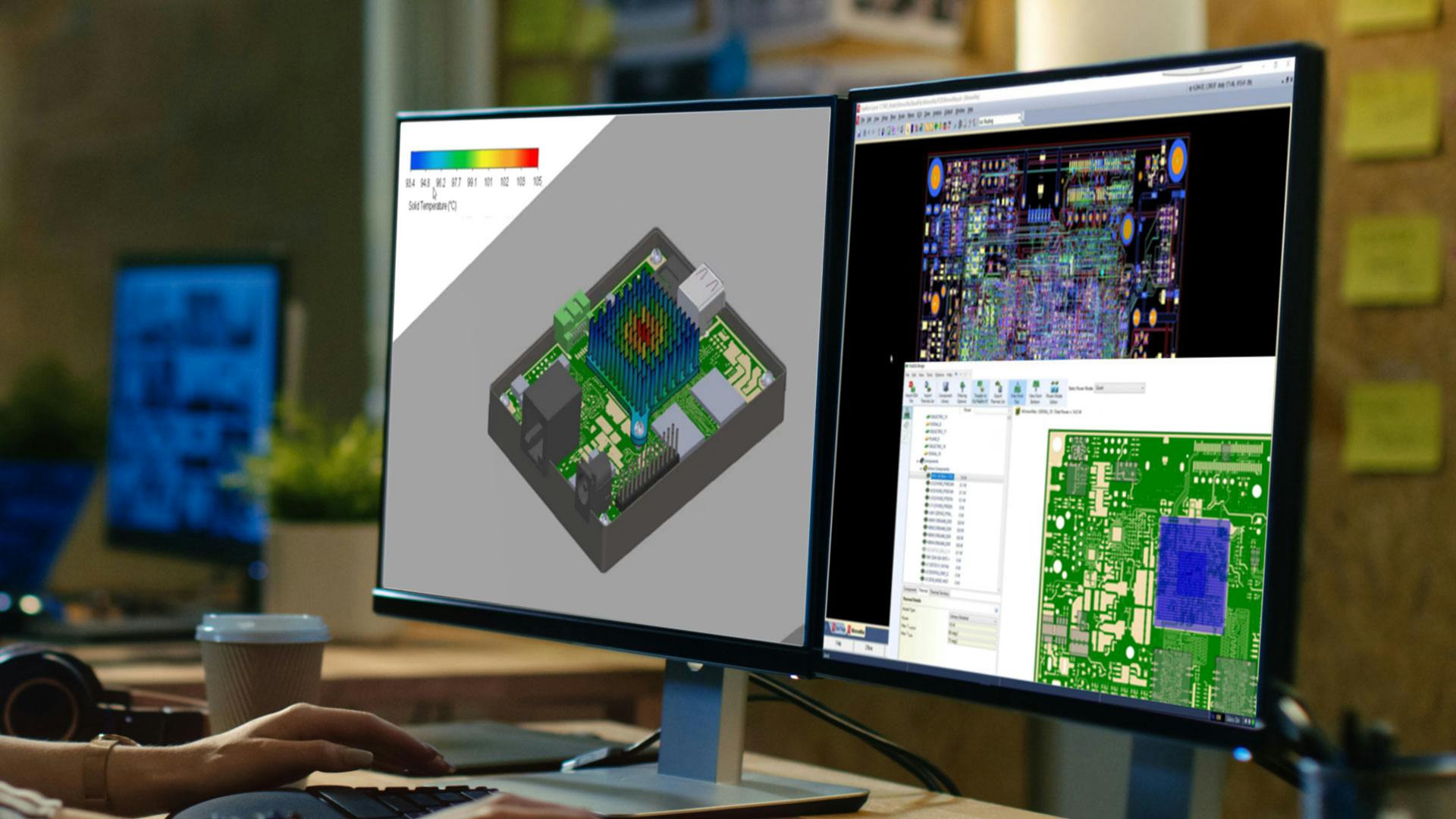

Electronics has become the main source of added value, revenue and profit in many industries, disrupting traditional mechanical design workflows. The main mechanical and electrical workflows are concerned with design, and design is “just geometry”. How do we know what is being designed will perform acceptably? There is a need for the design effort to be simulation-driven, with performance confirmed at every step along the way. Thermal design is one of the most vexing challenges in the physical design of smart products. Thermal simulation requires far more information than just geometry, and for simulation-driven design performance must be assessed before we commit to design decisions.

In this webinar, we will discuss the macro-trends and how mechanical and electrical design workflows are being combined to address the top cause of PCB re-spins in late design. We will explore options for creating simulation models before MCAD and ECAD data is available, understand options for dealing with MCAD and ECAD data, and analyze specific needs in context of active power management control strategies for smart products.

What you will learn:

- An overview of the state-of-the-art in exchange of ECAD-MCAD geometric data

- The importance of taking a simulation-driven design approach for the physical design of electronic products

- The challenges that simulation-driven design brings, with a focus on thermal design of smart products

- The pragmatic approaches that can be taken to representing ECAD and MCAD data in early design

- Solutions for using data from ECAD and MCAD systems in thermal simulation across the development lifecycle

Who should attend:

- Engineering Directors

- Development Managers

- Research & Development Engineers & Scientists

- Thermal Engineer & Designers

- Thermal Specialists

Seznamte se s přednášejícím

Dr. John Parry

Strategic Business Development Manager, Simulation & Testing Solutions

Parry, the industry lead for Simcenter solutions for the electronics and semiconductor industries, was the general chair of the SEMI-THERM 21 conference. He serves on the JEDEC JC15 Thermal Standards Committee, and on various conference committees. Parry has given several invited and keynote talks related to CFD, electronics cooling simulation and thermal characterization. His technical contributions to the discipline of electronics cooling include developing compact thermal modeling methodologies for fans, heat sinks, chip packages and LEDs. Parry also has expertise in design of experiments, optimization, thermal characterization, and active power cycling.